|

|

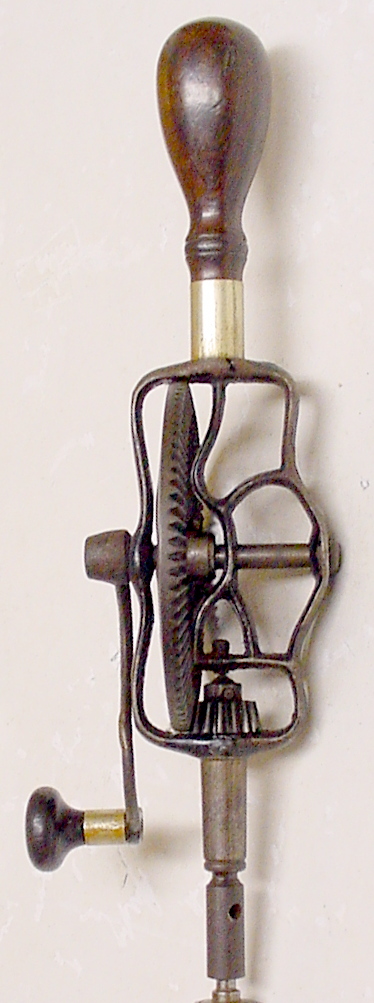

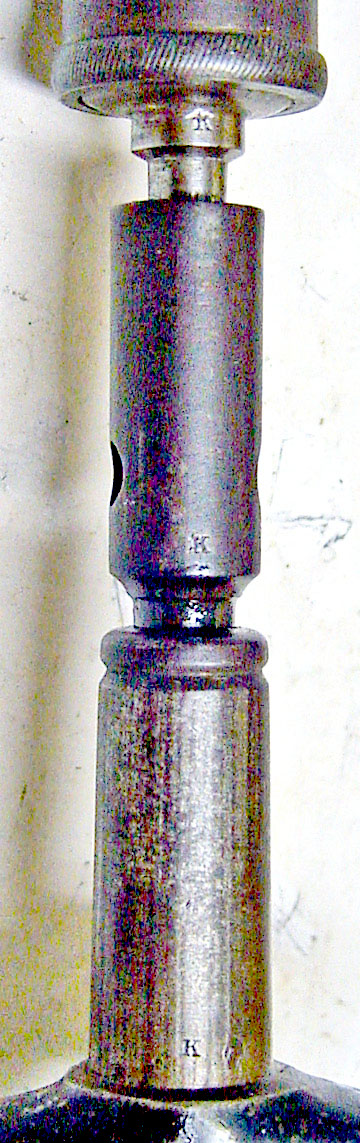

These three

drills were all hand-fitted in batches. The two cast-iron-framed ones

at far left were stamped with letters H & K, respectively, and the

bronze-framed drill to their right was stamped with the numeral 3,

suggesting that the cast iron examples were made in a batch larger than

ten, and the bronze example in a batch of less than ten. The markings

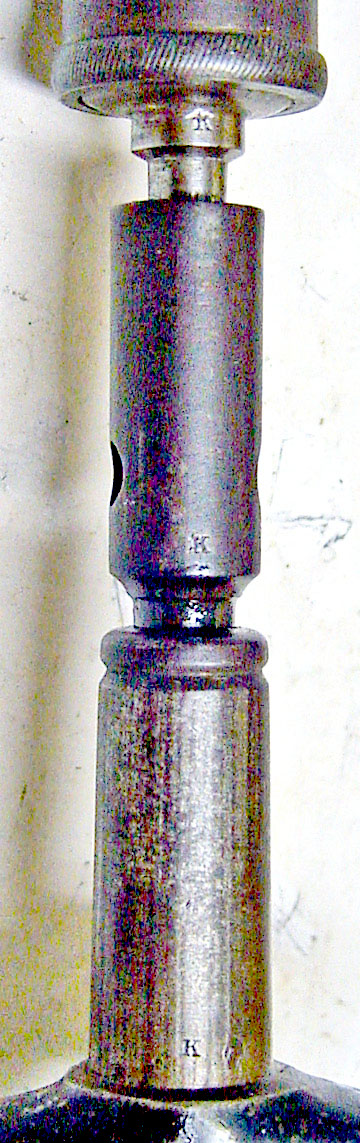

are located on the spindle & frame of the "H" drill; on the

spindle, frame and chuck of drill "K"; and on the spindle, frame, and

even the pinion gear of drill "3". The K-marked chuck fits both H &

K drills.

|

|

|

I

have a Pratt

& Whitney metal planer that is also match marked (with the

numeral 8); it was made about 1876. The Type

O

drill that Sandy Moss found is fitted with an 1877-dated two-jaw

chuck made by Millers Falls.

Those observations suggest that these three drills were made at or

about the time of the 1877 chuck invention, right after the wraparound

frames of the cast iron drills were redsigned to be slender enough to

become chilled in the casting mold and therefore convertible to

malleable iron by a later heat treatment, which made them ductile and

also soft enough to be easily machined.

Speculating even further, the bronze-framed Type P drill would have

been made in a small batch as

practice to perfect the machining setups to be followed in production

of larger batches of the malleable-iron framed drills.

|

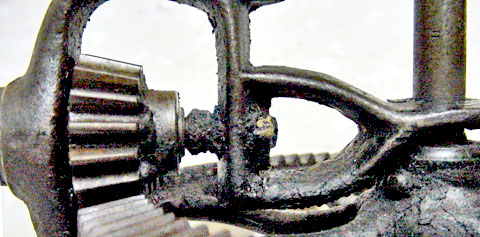

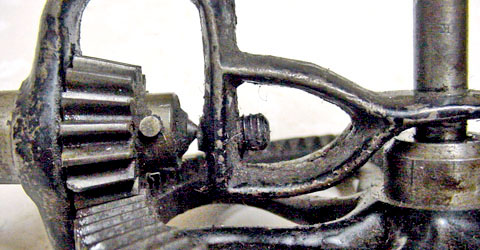

The "K" match marked drill's crank has a skillfully executed braze repair (image at far left, above).

|