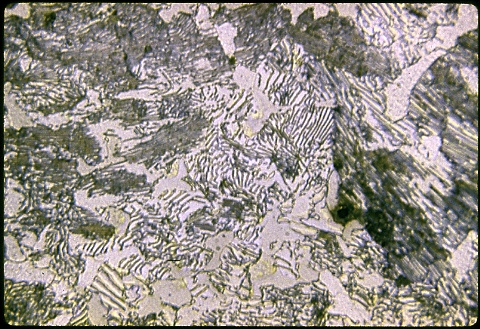

In the middle photomicrograph below at 500X you can resolve the microstructure better. There is a mixture of proeutectoid ferrite and pearlite which formed from austenite of near eutectoid composition. Evidently, the carbon content is subnormal in this part of the specimen, and the cooling rate during annealing was too rapid to permit the pearlite to spheroidize while it was forming.

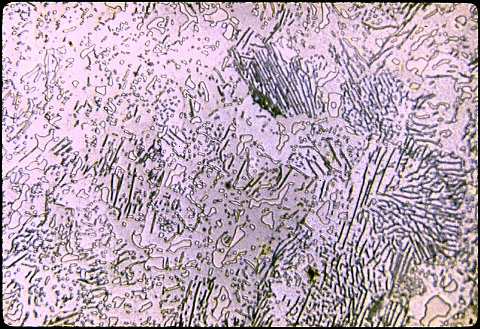

The last specimen in this lesson is a tool steel which was abusively cut with an abrasive disk.