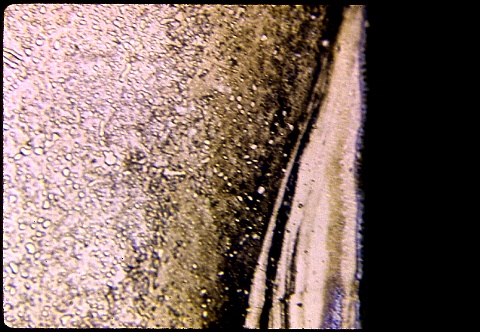

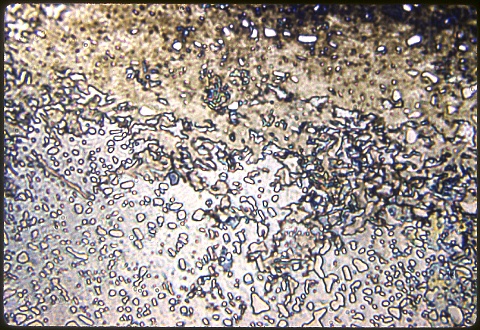

There is a hard spot resulting from local austenitization from the frictional heat. The hard spot ruined a cutting tool during subsequent machining. Traces of the cutting tool were deposited on the workpiece at this hard spot.

The trace is the light etching wedge to the right in the upper frame.

It is darker etching because the fresh martensite was tempered by the heat remaining in the metal from the cutoff sawing.