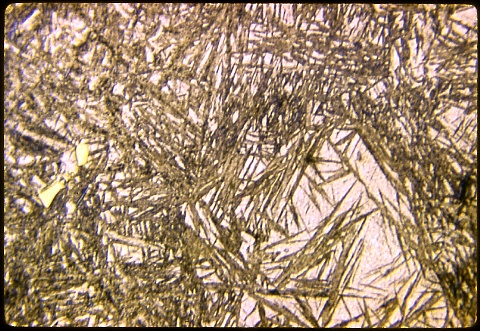

The photomicrograph at left was made at 50X with a Nital etch in the center of the specimen.

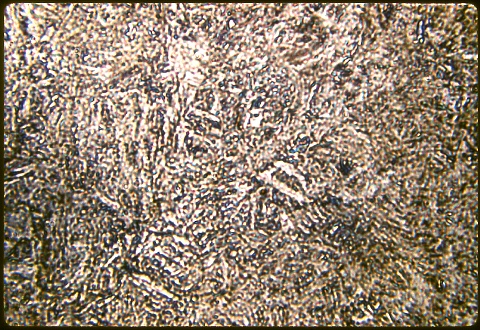

The image below was made at 500X in the same place.

|

This set of pliers, made of SAE8650 steel, was austempered

by isothermal transformation from austenite (formed at 840C in 20

minutes) to lower bainite at 300C. This specimen was held for too

short a time at the lower temperature - only 20 minutes. The photomicrograph at left was made at 50X with a Nital etch in the center of the specimen. The image below was made at 500X in the same place. |

The gold colored euhedral

particles at the left side of the 500X photomicrograph at left are

probably TiN, titanium nitride. This compound is extremely hard;

many modern drill bits come with a TiN coating (usually mis-spelled TIN

or tin) for wear resistance. The gold colored euhedral

particles at the left side of the 500X photomicrograph at left are

probably TiN, titanium nitride. This compound is extremely hard;

many modern drill bits come with a TiN coating (usually mis-spelled TIN

or tin) for wear resistance.This microstructure demonstrates the effect of segregation on hardenability; the outer parts of the piece are bainite,but the inside has (light colored) untempered martensite in addition to the bainite, because the transformation from austenite to bainite wasn't completed there in the 20 minute hold at 300C. The untransformed austenite became martensite upon subsequent cooling to room temperature and has not been tempered. A good remedy for this undesirable microstructure would be to temper the pieces at just under 300C to give the unwanted martensite some toughness without softening the bainite, which doesn't need tempering. Austempering is usually done to impart toughness to a workpiece with a complicated shape. There would be too much danger of quench cracking in a conventional quench and temper heat treatment of such a part, and air hardening steels are more costly than less hardenable steels. There are far lower quenching stresses during the austempering treatment because the cooling from 840C to 300C does not cause any phase changes anywhere in the piece, and because the relatively slow isothermal transformation of the austenite to bainite goes on everywhere in the piece more or less simultaneously under little or no temperature gradient, as the entire piece has cooled to 300C before much transformation has taken place. |

|

Here, shown at 1000X with a

Nital etch, is the good bainitic microstructure (which consists of

ferrite plus cementite in a slightly different morphology than in

tempered martensite) in the outer part of the specimen. SAE8650 steel nominally contains 0.5% carbon, 0.8% manganese, 0.3% silicon, 0.5% nickel, 0.5% chromium, and 0.2% molybdenum. The last three elements provide most of the improved hardenability over a plain medium carbon steel. |

|

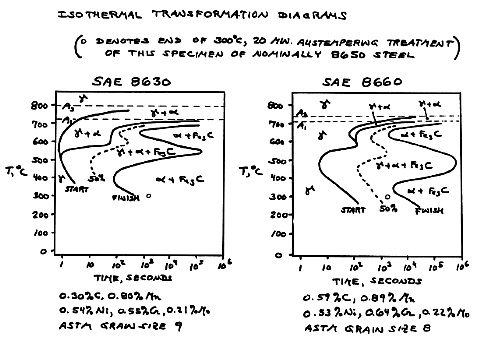

The time

temperature transformation (TTT) curves for two similar steels are

reproduced here. Note that the 20 minute (1200 second) heat

treatment at 300C was probably insufficient time even for the present

steel, were there actually 0.5% carbon instead of 0.6% carbon in the

right hand TTT curve. The tiny circle (o) in each diagram denotes the time and temperature used for these pliers. Specimen 4 is a tension member for prestressed concrete. |