The

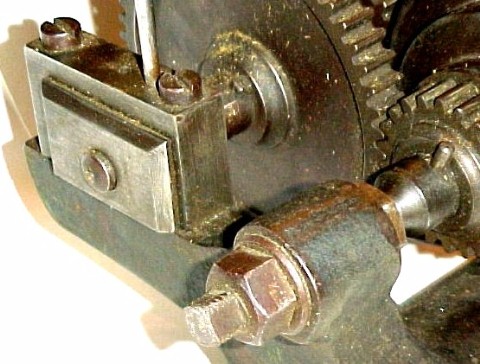

end thrust

of the spindle of this lathe bears against a dead center, and the main

bearing

appears to be bored directly into the iron headstock casting.

There

is an oil hole above the front bearing, but it appears never to have

held

an oil cup. The back gear mechanism is engaged quite unlike a

modern lathe, because the engagement is effected by pulling

out a pair of taper pins and sliding the gear carriage for and aft.

Every back-geared

lathe in has the eccentric & lever mechanism that is familiar

to most machinists. The lack of a hole through the spindle, the

stationary cross slide, and the archaic back-gear mechanism together

indicate that the builder of this lathe had limited resources - a shop

lathe not much bigger than this one with only a steady rest to support

the new spindle while its center hole was bored - no planer to true the

ways of the bed - and little experience visiting or working with other

machine tool builders. Furthermore, the lathe is driven by a

round belt, not a Vee belt, indicating that it was made before anyone

contemplated the need for the high power to cut with high speed steel

tools.

|

|

|

|

|

|

Rear of headstock

|

The center

has only a stubby little taper which one twists out with a wrench -

there

is no through hole in the spindle.

|

Tailstock feed

handle looks original.

|

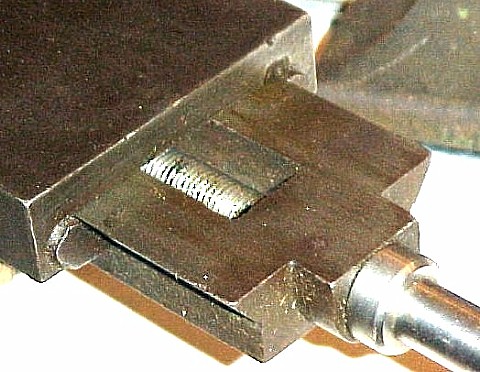

The crossslide

dovetails are inlaid steel.

|

|