Go back to Main Study Page

Type K2

|

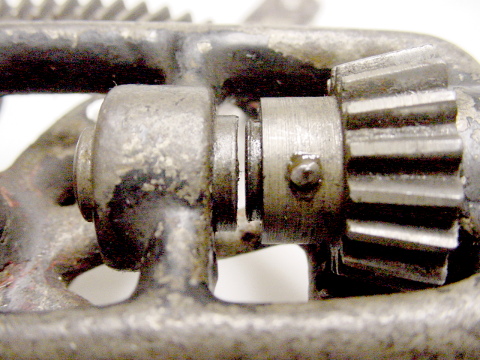

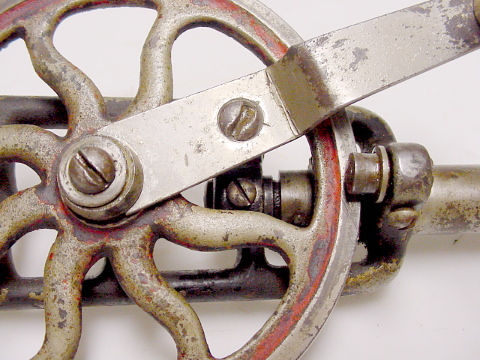

On the left: The Type K2 is the second of the LRRCW models. It still has no provision for a side handle. And the thrust bearing is still a simple cylinder adjustable from between the spokes of the main gear wheel in order to control the end play in the spindle. The adjusting screw can be seen peeking out from behind a spoke in the image at left. The main rosewood handle is in its slimmest form, but there is as yet no "breast pad" to aid in pushing on the handle, because the 1877 patent two-jaw chuck carried over from earlier No.2's could only hold bits 1/4 inch or smaller. The malleable-iron frame of the Type K2 is the wider version of the new model. Recovered at Brimfield thanks to a cash loan from Sandy Moss. Thanks, Sandy ! The crank and its handle appear original and carry no identification markings. Only the chuck carries the "Millers Falls Co." name. This drill is in amazingly good condition for a 125-year-old tool. The red and black paint job is original, and there is next to no loss of nickel plating which covers all parts, even underneath the paint of the main gear and frame. Only the pinion, LRRCW mechanism and spindle are uncoated steel. The very slim neck of the main handle remains strong because the straight tubular brass ferrule did not succumb to season cracking as do nearly all the later, deep-drawn ferrules of the No.2 Milllers Falls drills, which should have been stress relieved but weren't. On the right: Another one, this time with an unplated, simply japanned frame & main gear, and a well made hardwood main handle, also reinforced with a tubular brass sleeve. |

|

|

On the left: One distinguishing characteristic of the Type K drills is the flat cylinder used to resist thrust, with its simple clamp-screw adjustment, accessible between the spokes of the main gear. On the right: This crank knob had lost its ferrule, and I've replaced the parts with a new tubular brass ferrule, peened into place with a 2 ounce Stanley hammer. |   |

Note: Here's another Type K drill, made by Millers Falls for sale under the Winchester trademark.