A Research Study

by George Langford, Sc.D.

Return to Main Page

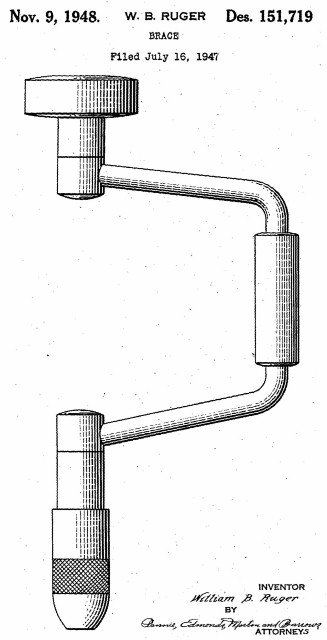

BRACE 1

| William B. Ruger obtained a US

Design Patent,

No.D151,719, for the outline of a brace on November 9, 1948, with a

duration of 3-1/2 years. With that degree of protection, three

models

of brace were made, one marketed under the A.R.T.I.S.A.N

trademark,

another under Ruger's assignee, the Ruger Corp. of Southport, Conn.,

and the third marketed by the former Seymour Smith & Sons, Inc. of Oakville,

Conn., a distributor of arborist tools. The last of these is

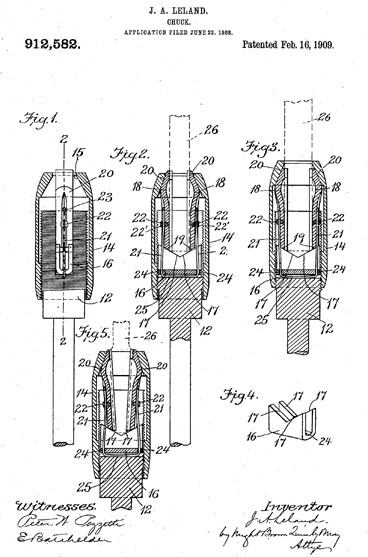

illustrated below as their No.2310. The chucks used in these braces follow the design of the John A. Leland's US Patent No. 912,582, assigned to the Millers Falls Company. That patent would have run out in 1926, more than twenty years before the Ruger braces illustrated here were made. Therefore, it is hardly a proof of Millers Falls parenthood that the Ruger braces' chucks were patterned after the Leland patent. |

| Brace 1: Seymour Smith & Son

version of D151,719: |

William B. Ruger's US Design Patent No. D151,719: |

John A. Leland's US Patent No. 912,582 for the same chuck

used in the Ruger-designed braces: |

|

|

| The inside of the ratchet isn't worn (49 teeth) |

Parts mostly out: |

The cover is marked, and the selector is, too, although that

can't be seen here. There is an extra part, the shim 2nd from

left. Also, the selector is now a die casting. |

|

| Pawls & springs back in: |

Selector above slot: |

Selector detents: |

All back together: |

BRACE 2