|

Part I -

Adapting template gears with bores smaller than 3/4 inch to the Atlas

milling machine's indexing centers.

Just as I did for

my Sebastian

treadle

lathe,

rather than making any permanent, irreversible changes to the Atlas

milling machine's plain indexing centers, I made an adapter to enable

use of the South Bend lathe's change gears (which mostly have a 9/16ths

inch bore) as templates. Just as I did for

my Sebastian

treadle

lathe,

rather than making any permanent, irreversible changes to the Atlas

milling machine's plain indexing centers, I made an adapter to enable

use of the South Bend lathe's change gears (which mostly have a 9/16ths

inch bore) as templates.

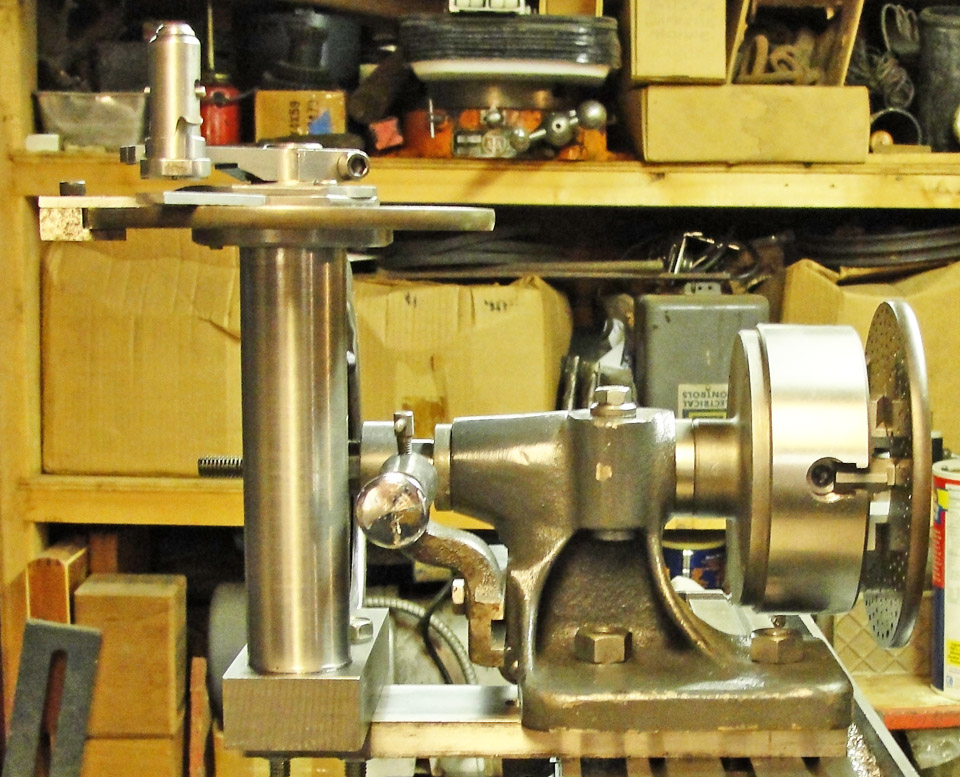

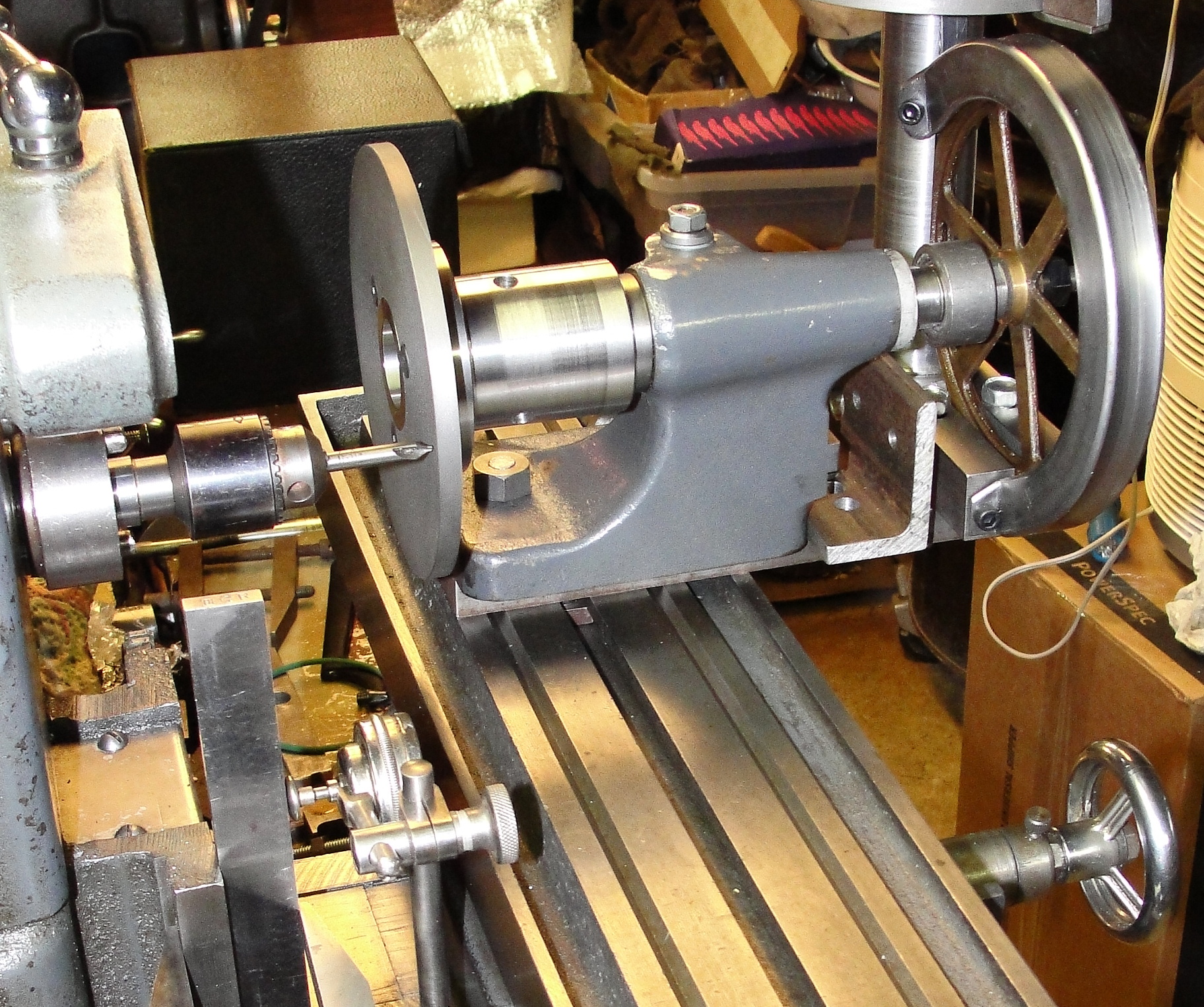

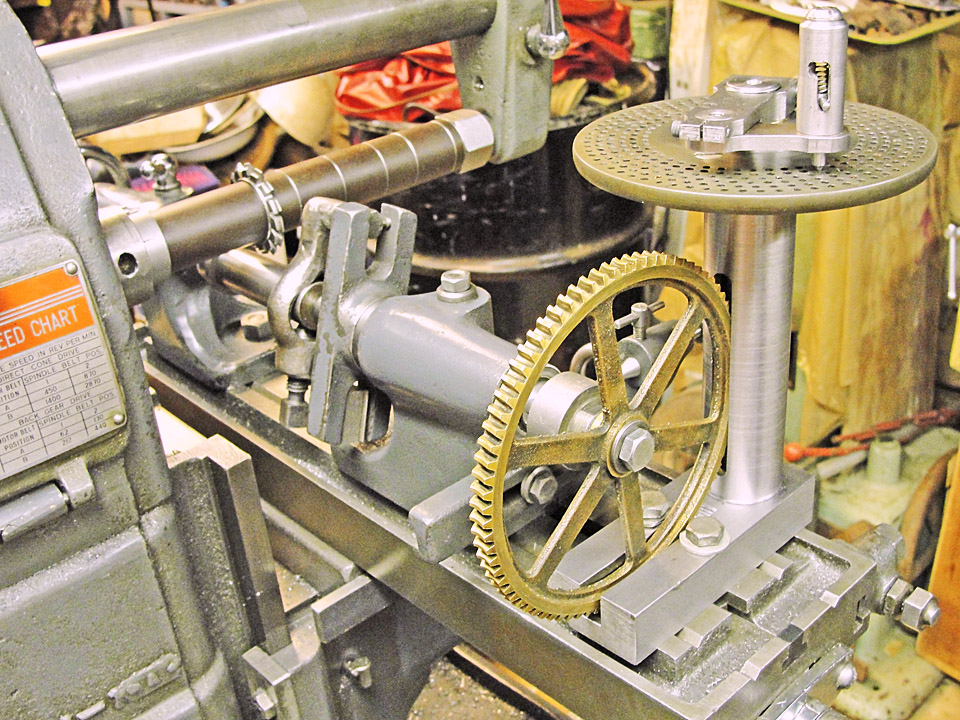

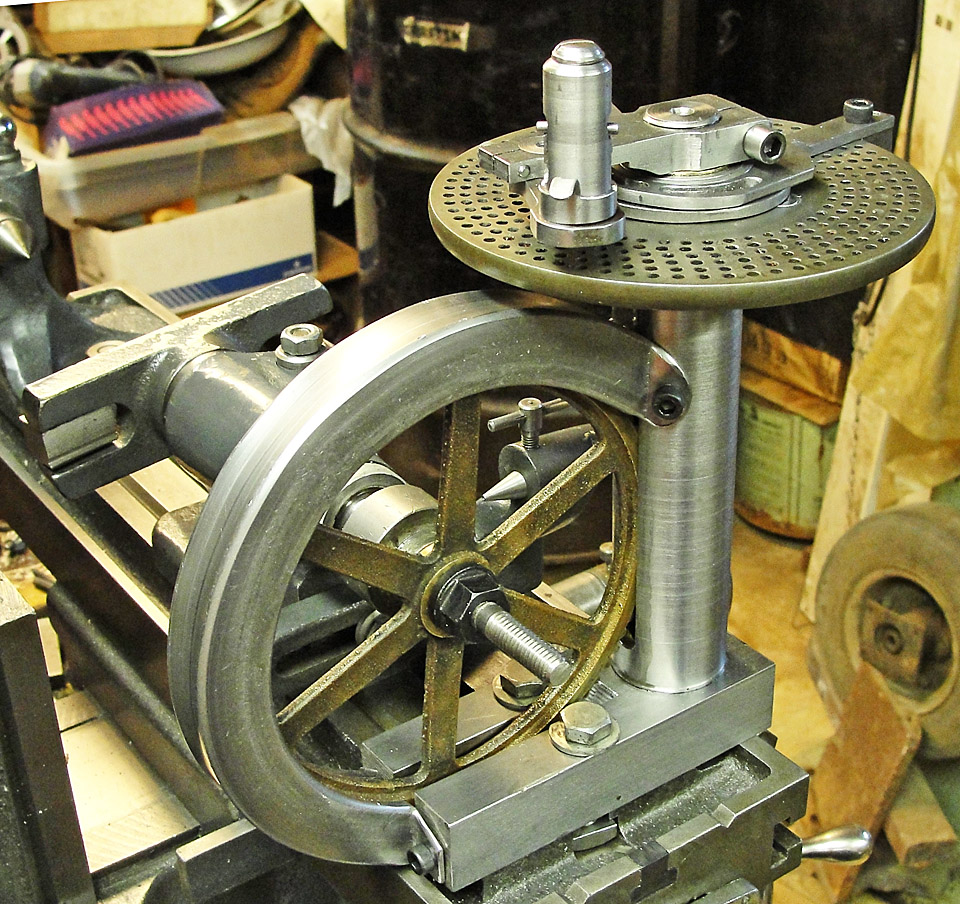

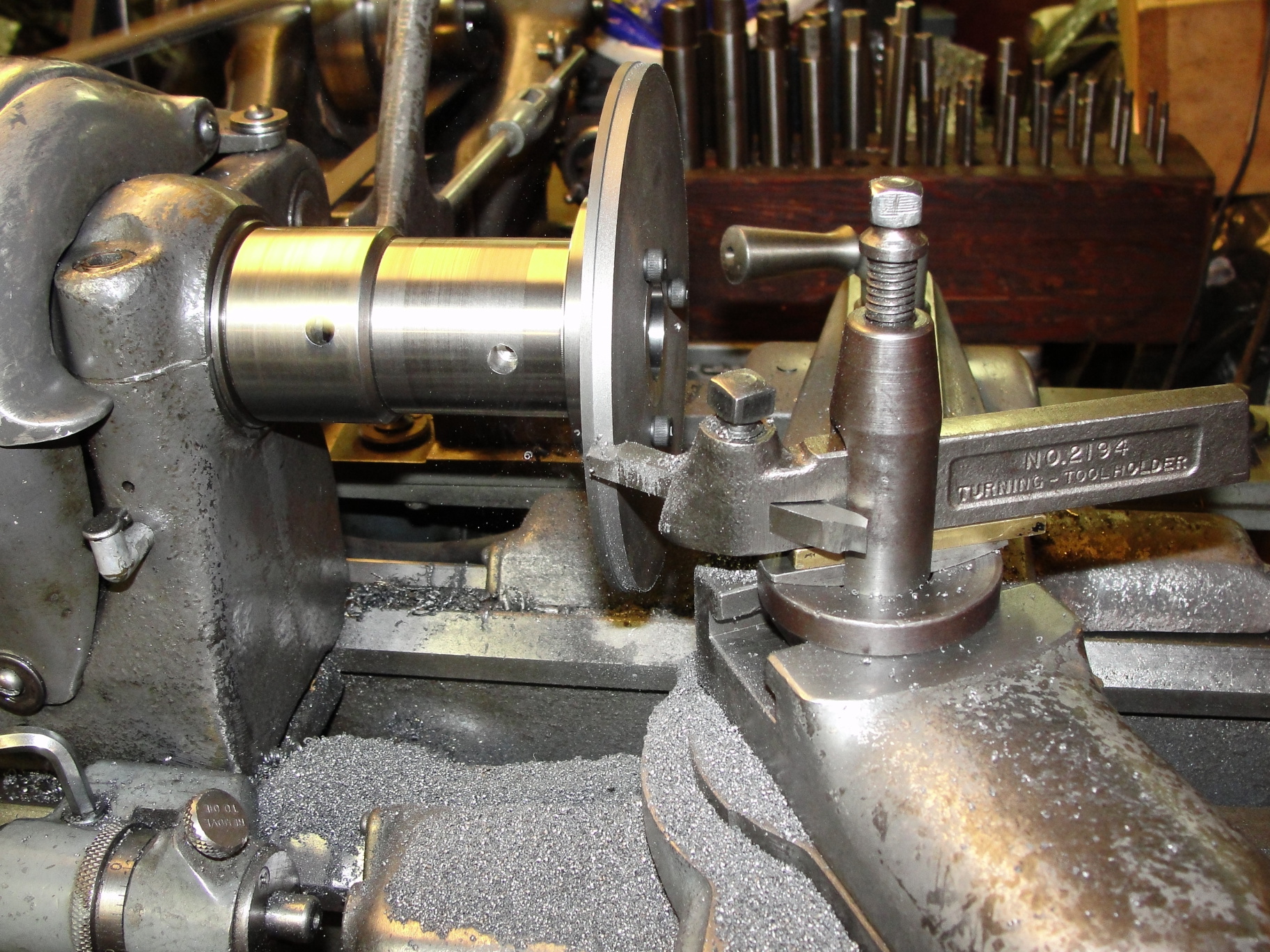

The adapter consists of a plug closely fit to the bore of

the

indexing center's spindle and incorporating a tapered collar that

matches the center bearing of the spindle, and which is clamped in

place by the indexing center's nut (shown sitting on the Atlas MM's

table).

|

The

adapter

also

has a sleeve to match the bore of the gear being used

as a template to the diameter of the adapter plug.

The

adapter

also

has a sleeve to match the bore of the gear being used

as a template to the diameter of the adapter plug.

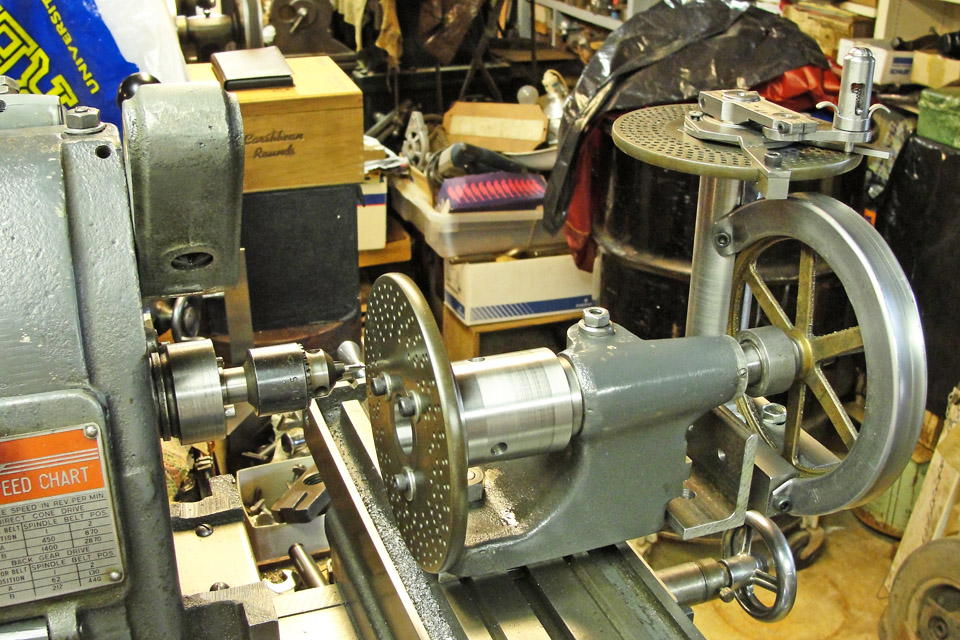

In the image at left, the adapter is holding a 100 tooth

change gear

(needed for making metric threads on the South Bend lathe) onto the

spindle of the Atlas milling machine's indexing centers. There is no

key used - the friction of the 5/16-18 clamping screw is sufficient.

Note the stops that I added to the longitudinal table

travel. held in place by the former gearbox screws.

|

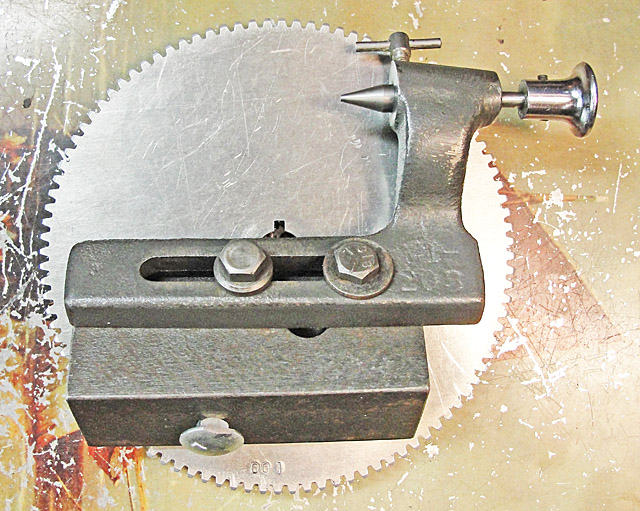

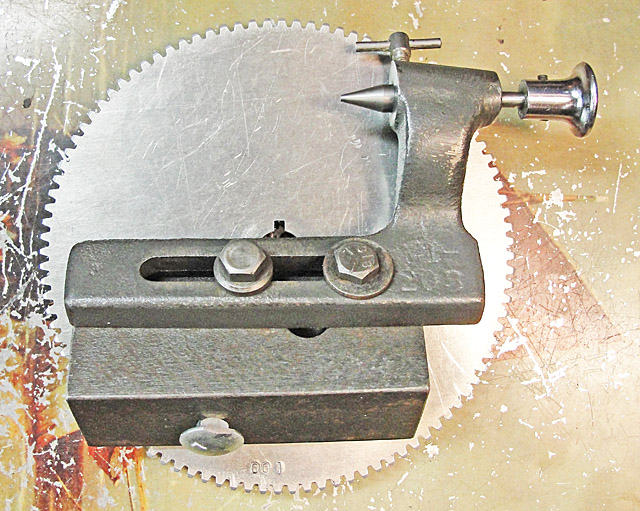

Another

necessary

part

of

the above adapter is an angle plate that

holds the indexing pawl, which simply clamps to the table of the Atlas

milling machine.

Another

necessary

part

of

the above adapter is an angle plate that

holds the indexing pawl, which simply clamps to the table of the Atlas

milling machine.

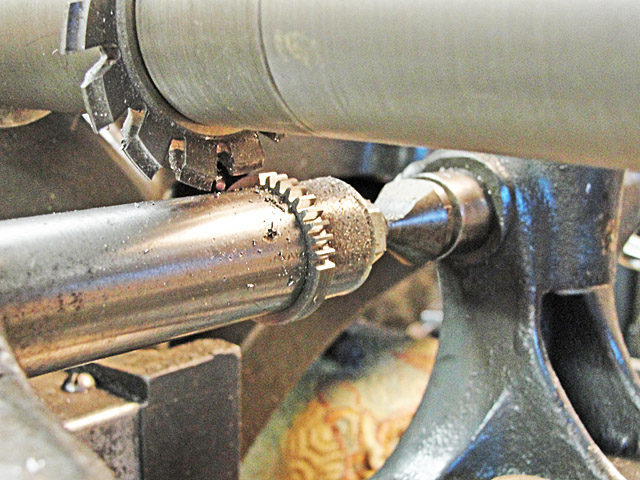

I made a new pin for the indexing pawl which has a 14-1/2

degree

cone to match the pressure angle of the template gear. The Atlas

indexing centers come with a pin whose nose radius is a bit too large

for the smaller gear pitches.

The angle plate has three mounting holes for the pawl

carrier so

that it can be appropriately placed for any template within the range

of the milling machine.

|

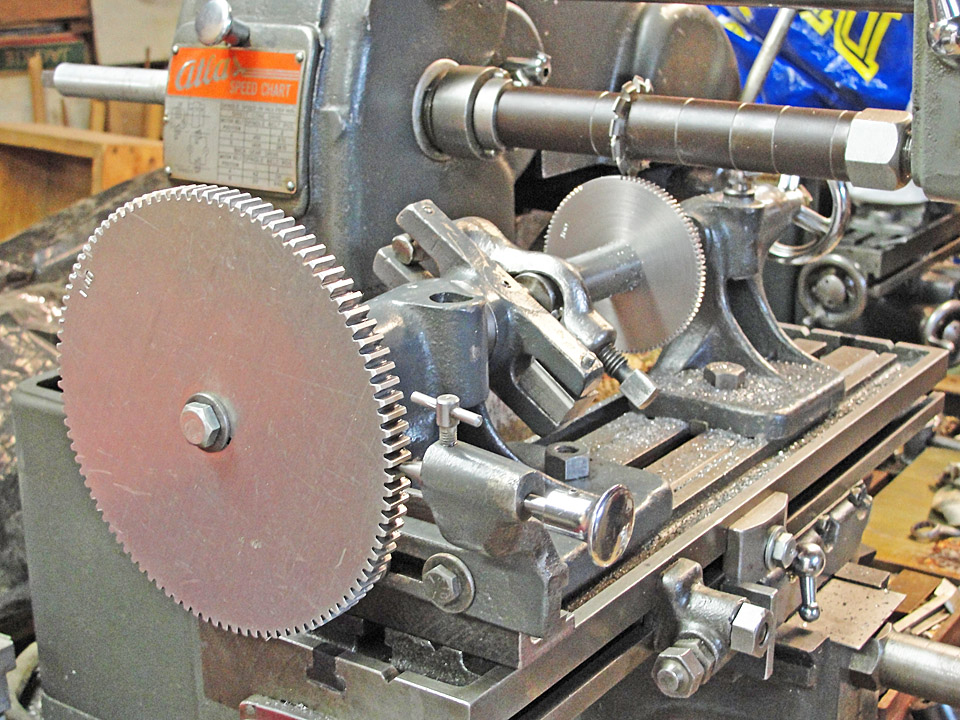

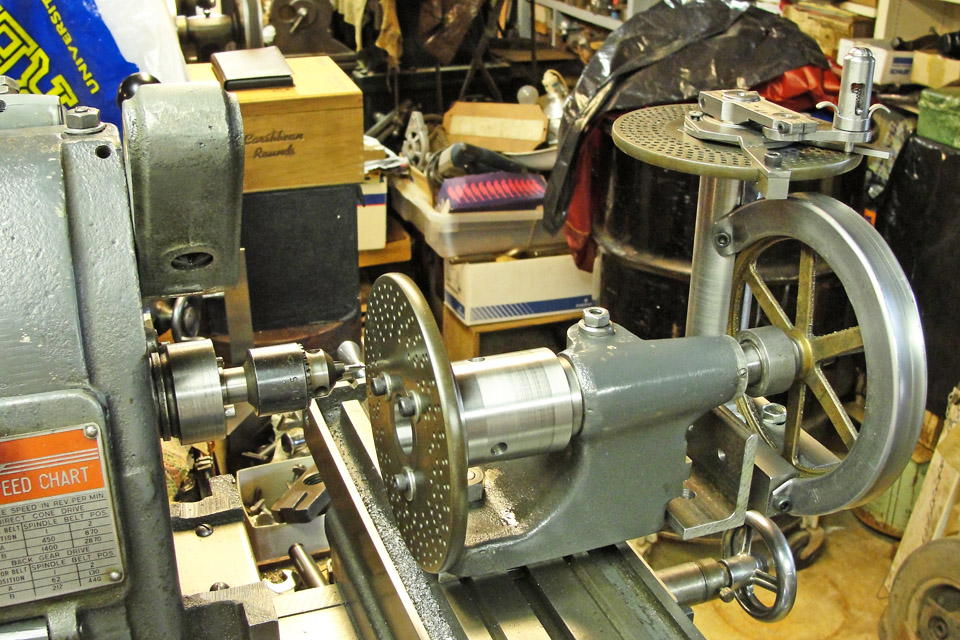

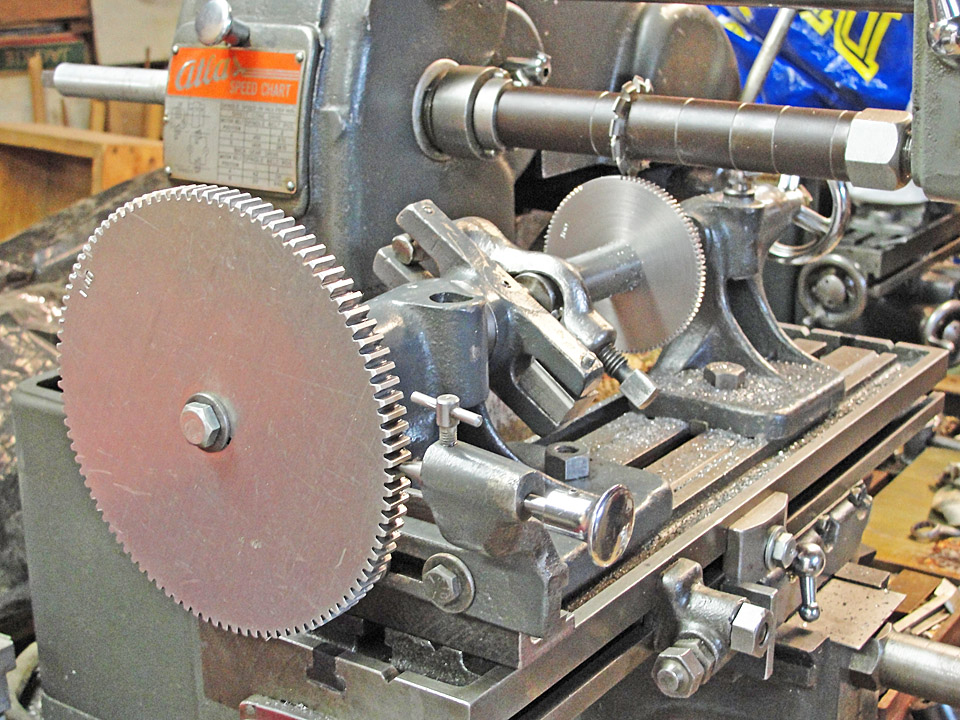

As seen in the image at left, even template gears which

the indexing

centers cannot swing over the table of theAtlas milling machine can be

hung over the end of the table.

The 100 toth gear being made here is 32 diametrical pitch,

intended for my Goodell-Pratt

29-1/2

"treadle"

lathe's

screw threading adapter.

|

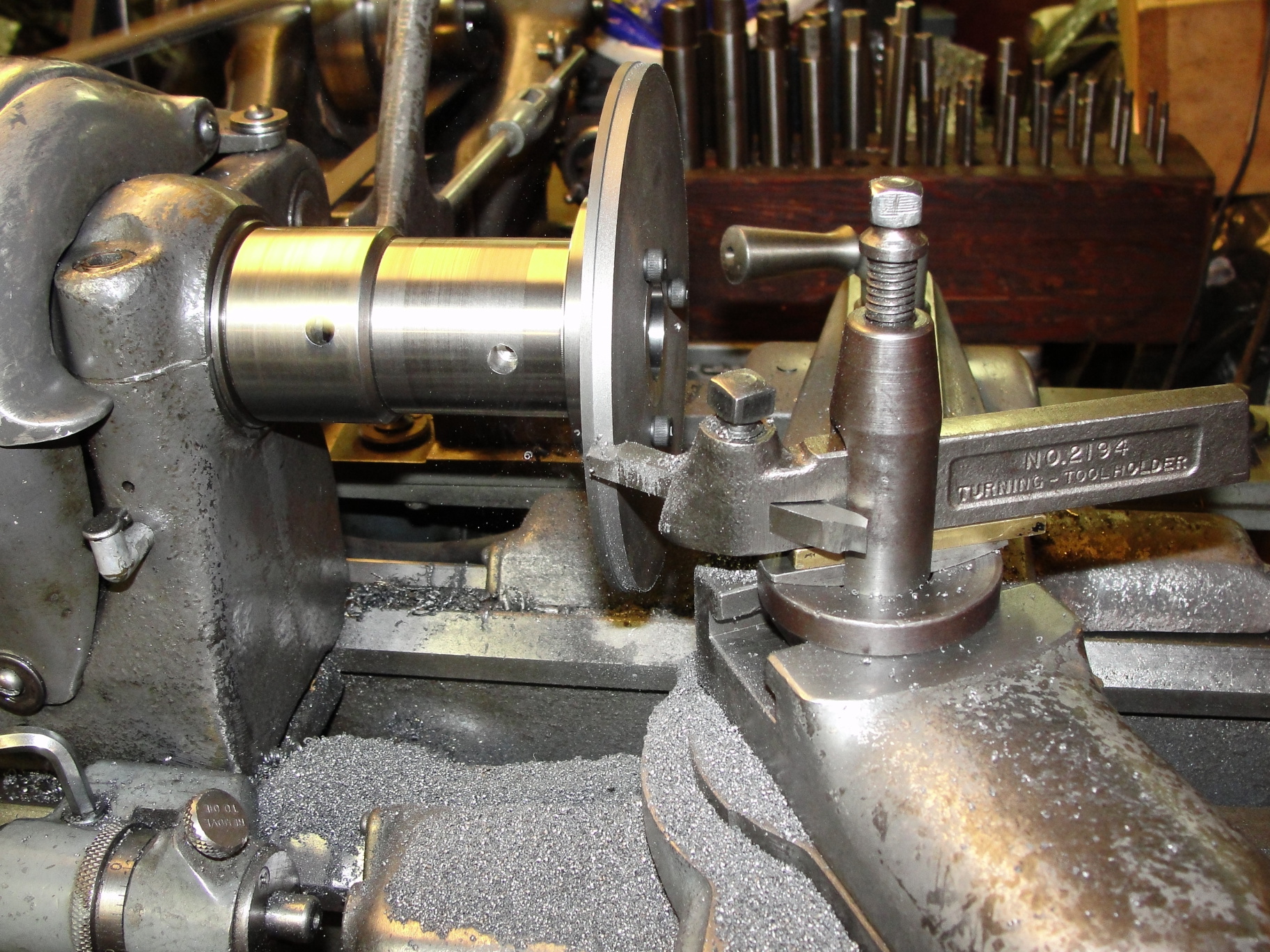

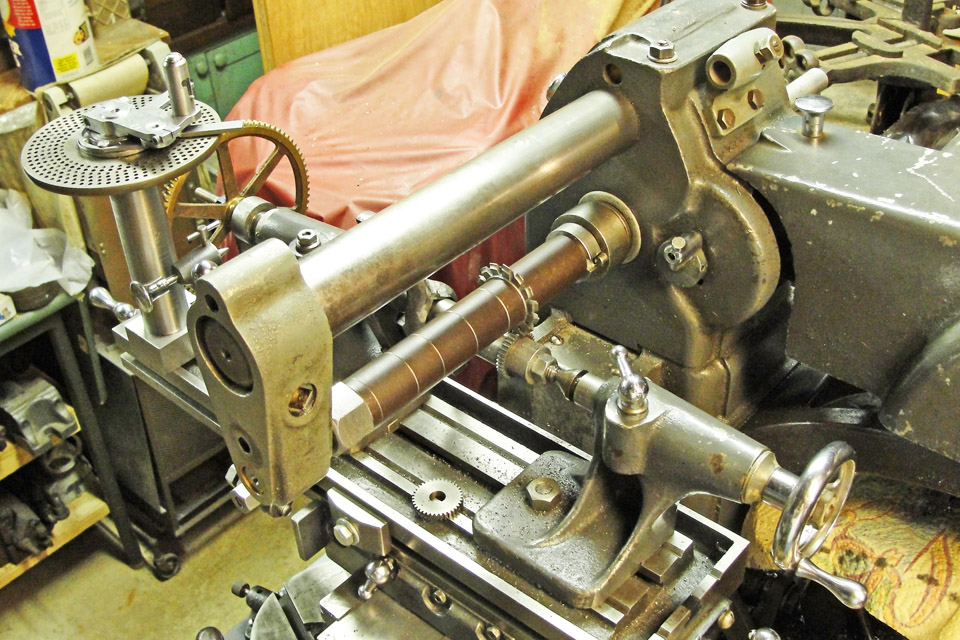

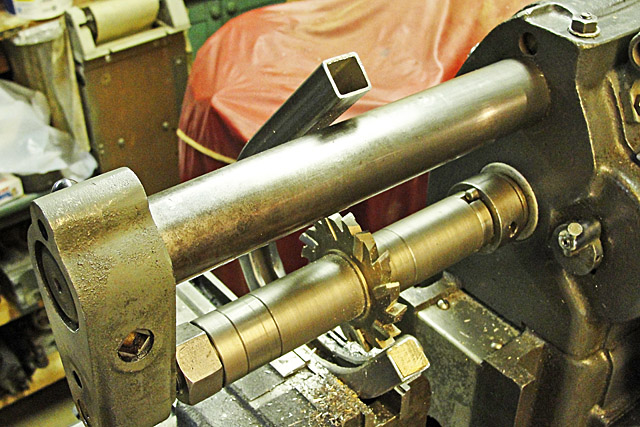

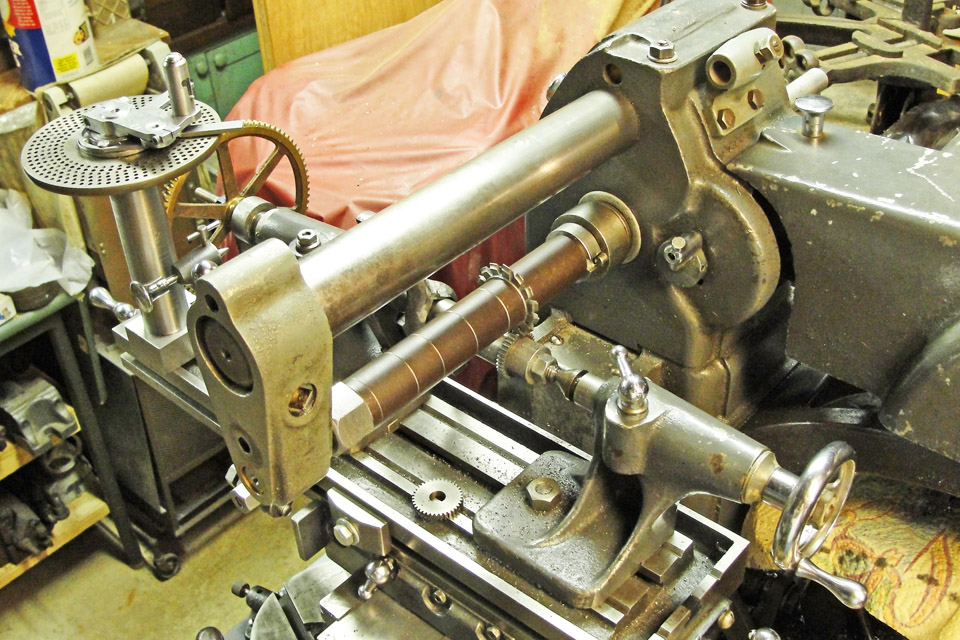

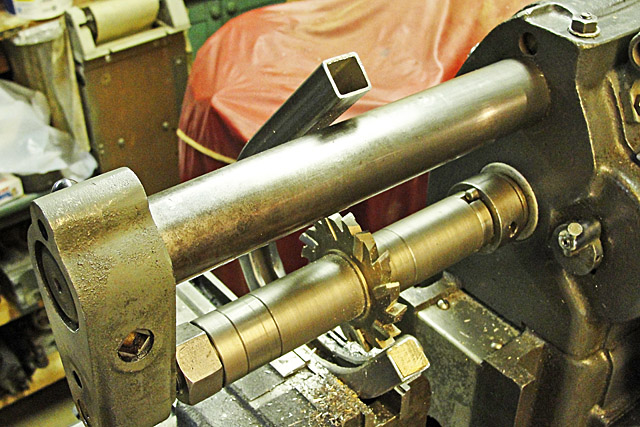

The 36-tooth gear shown in process at left is being made

on an arbor

which I made that would be stiffer than the tapered arbors used

previously, which do not hold the gear blank securely perpendicular to

the arbor axis and which deflect excessively in the smaller sizes, such

as 3/8 inch.

The arbor has a threaded extension sized to fit the gear

blank's

bore and a loose collar to facilitate making more than just one gear at

a time and to place the threads of the arbor outside the bore of the

gear blank.

|

The arbor is driven by a lathe dog and is carried on the

two centers of the indexing head.

That's a 72-tooth template gear (from the set that came

with the indexing centers) in the background.

This arbor is far stiffer than a simple tapered arbor and

helps to

prevent most of the chattering that is created by interactions between

the arbor and the knee of the milling machine.

|

|

|

Part II -

Freeing the Atlas milling machine's indexing centers from the need for

templates.

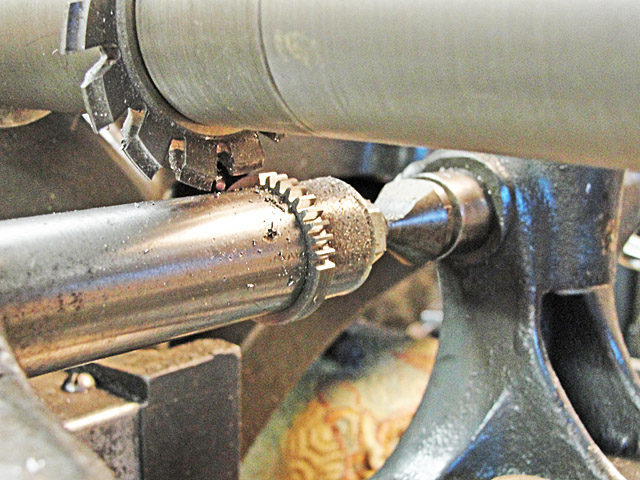

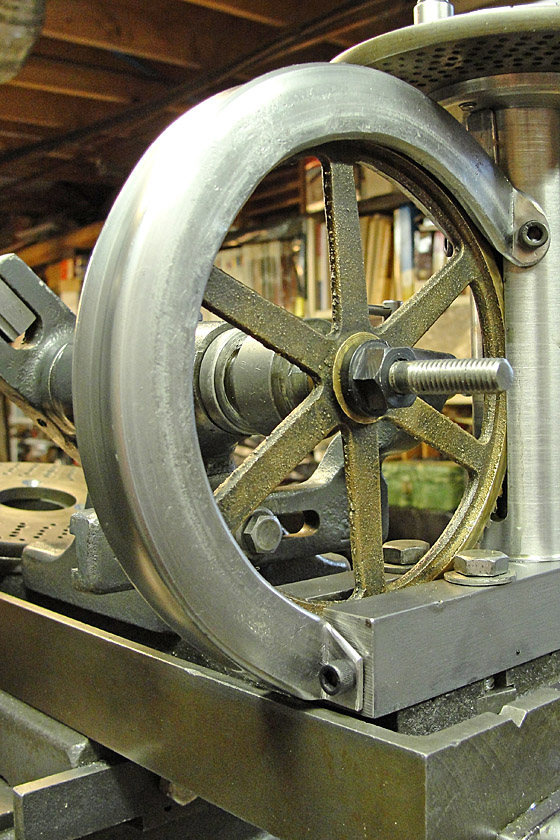

While rummaging through my parts drawers in

search of 32 DP gears, I came across this 80-tooth worm gear.

That's just twice the number of teeth in a standard universal index's

40-tooth worm gear, so I decided to put my found gear to use. While rummaging through my parts drawers in

search of 32 DP gears, I came across this 80-tooth worm gear.

That's just twice the number of teeth in a standard universal index's

40-tooth worm gear, so I decided to put my found gear to use.

The 5/16-18 tpi cap

screw and plain washer did not hold

the

80-tooth worm gear securely, so I used a 5/16-18 tpi stud and flanged

nut

from the workpiece clamping set for the Atlas miling machine instead.

|

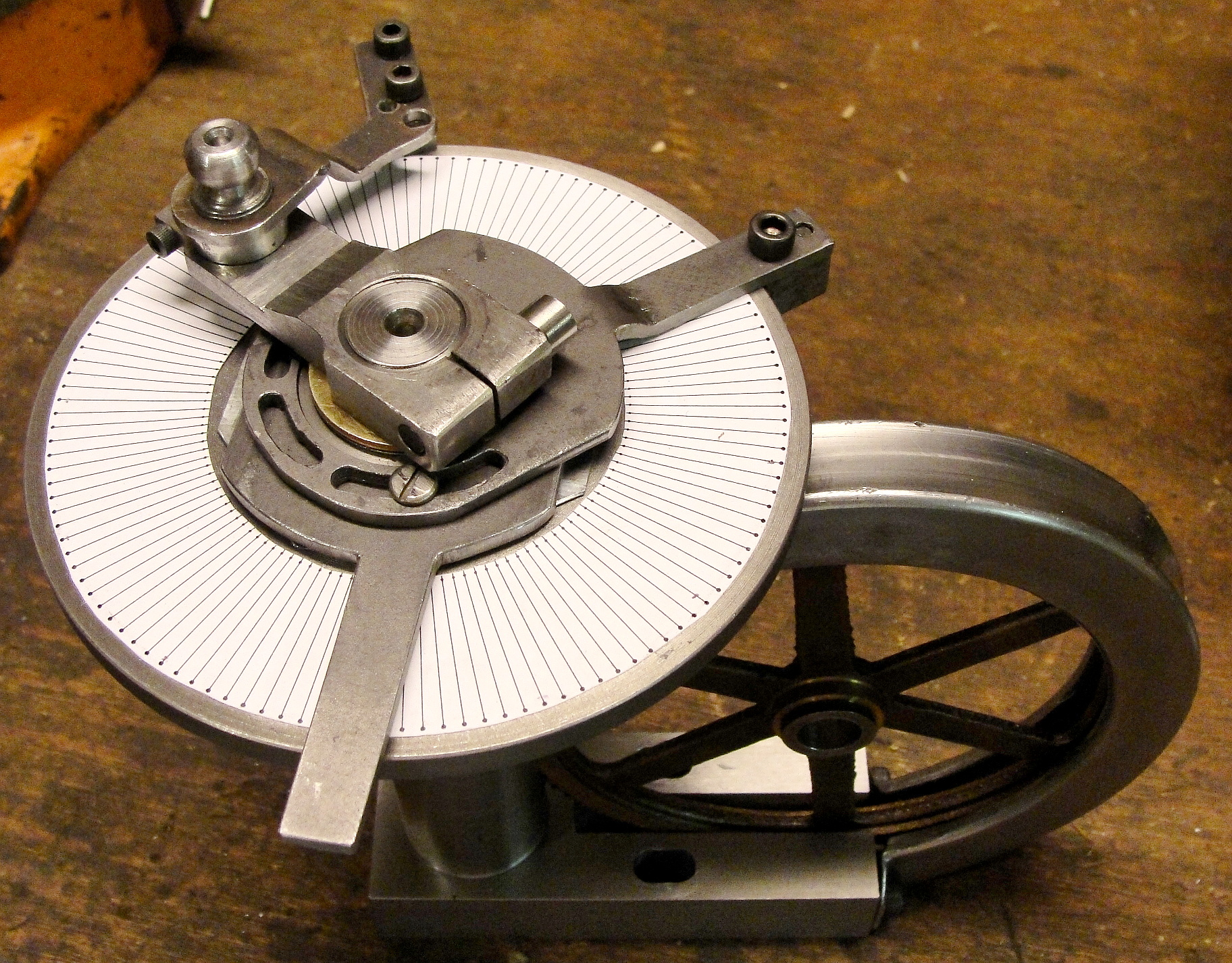

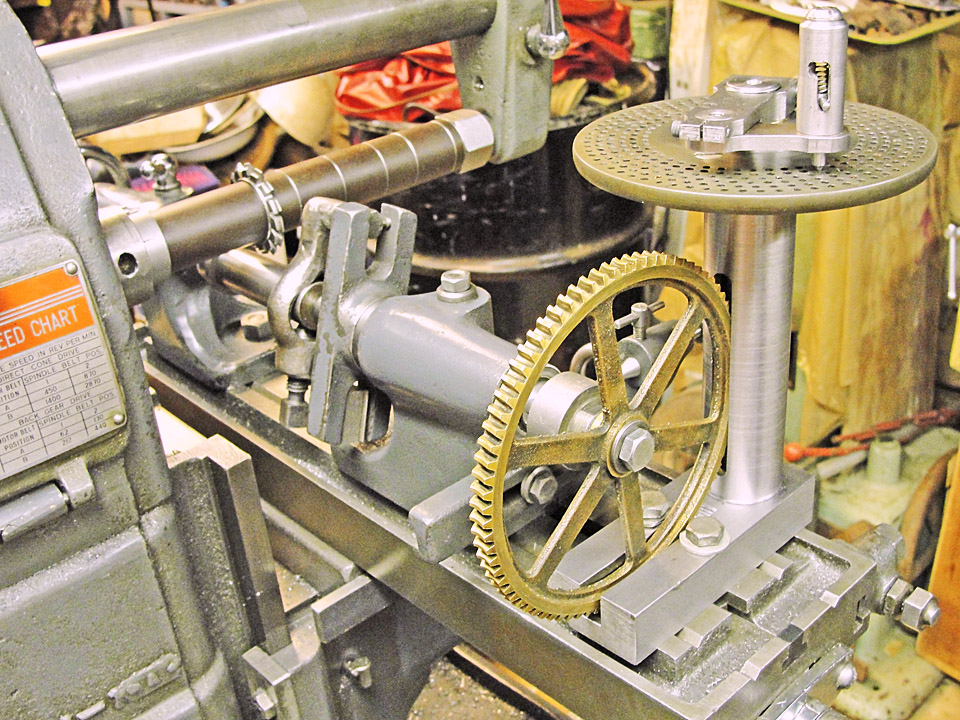

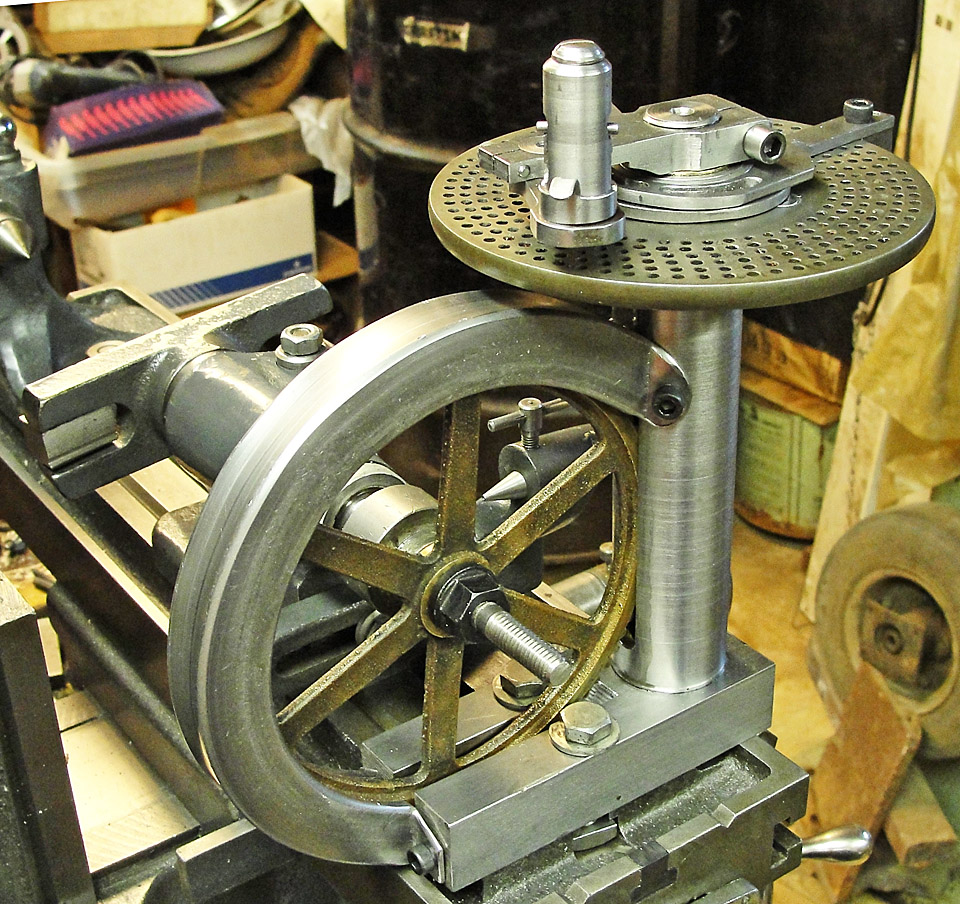

The indexing plates came from a CRAFTS of NJ tailgating session, I

think ... or from a Cabin Fever auction ... I made the crank from

scratch, using the experience I gained from making a banjo for my Derbyshire

lathe thread cutting adapter.

The indexing plates came from a CRAFTS of NJ tailgating session, I

think ... or from a Cabin Fever auction ... I made the crank from

scratch, using the experience I gained from making a banjo for my Derbyshire

lathe thread cutting adapter.

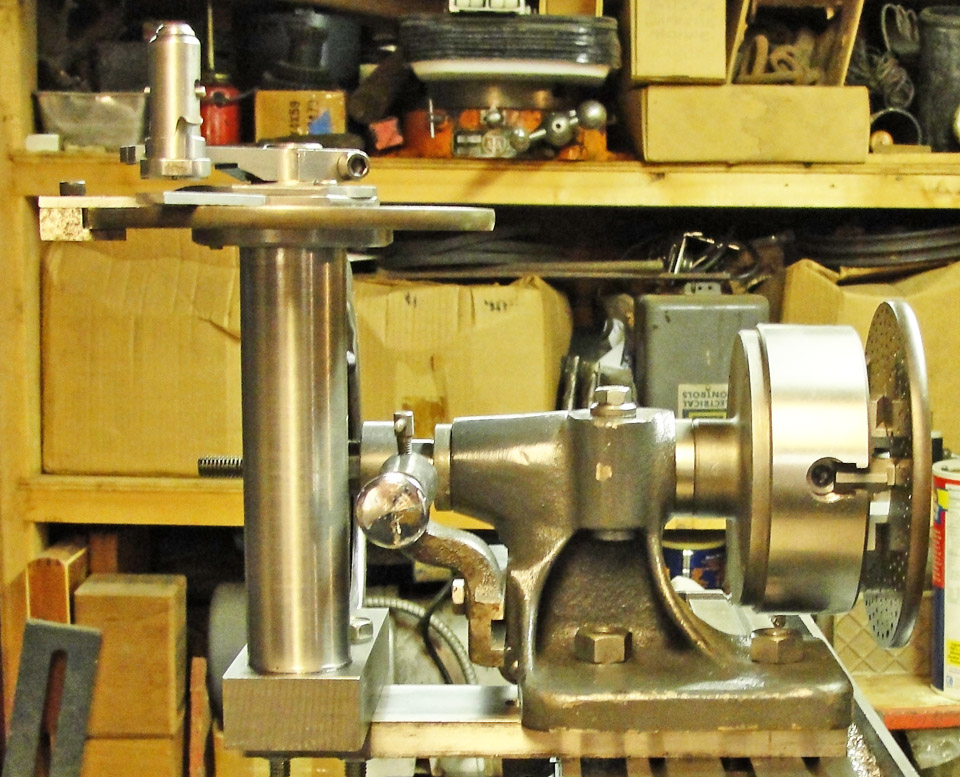

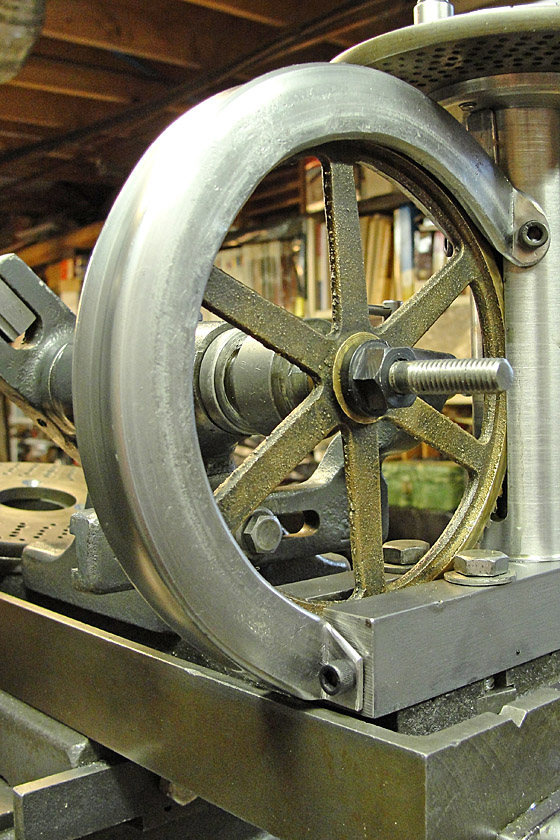

Shown at left is the first

assembly of the gear to the adapter

which I made that permits the gear to drive the spindle of the Atlas

milling machine's indexing centers without any permanent

modifications. The vertical cylinder is press fit to its base and

carries a 3/4-5 tpi Acme-threaded worm in bronze bearings.

|

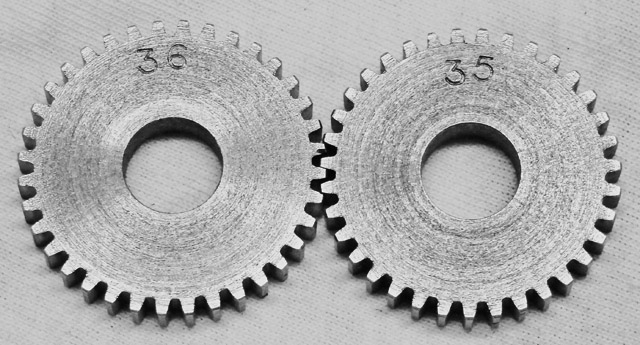

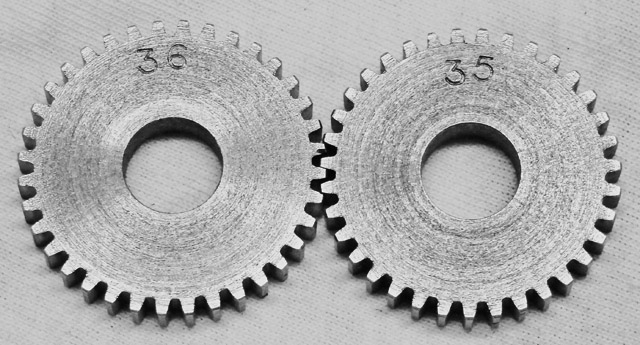

The 36-tooth 32 DP gear at far left was made using a

72-tooth Atlas gear as a template, whereas the 35-tooth gear to its

right was cut with the 49-hole index in the newly upgraded Atlas

indexing centers using one and 7/49 turns of the crank executed twice

per tooth.

The gears mesh perfectly !

|

Still to come:

I. A guard to protect the delicate 80-tooth cast bronze worm gear,

being made by bending a piece of 3/4 inch square steel tube to a ca.

2-1/2 inch radius and then milling a 3/8 inch wide slot around its

inner perimeter. The bending task is complete; I didn't break anything

or get too sore.

II. An accessory to protect my fingertips while lifting the indexing

pin of the crank. The present 1/8 inch cross pin's tips are too small

for the rather strong spring that forces the pin into the circle of

holes in the index plate.

III. I already made a clamp that prevents inadvertent movement of the

indexing sector, which can be disastrous when it occurs during cranking

of the worm while gear-cutting.

IV. Now I need a bunch of 5 inch diameter indexing plates ...

|

Part III -

The promised extras.

The

gear guard started out as a 16 inch long piece of 3/4 inch square

welded tubing, which I was able to bend cold with the aid of a cheater

bar and a piece of heavy steel tubing that was just the right diameter

around which to form the more-than-180 degree curve of the guard.

A bar clamp allowed me to complete the bending task, as it let me bend

the tubing with my own hands without great effort. Of course, I

filled the tube with fine sand and hammered in oak plugs to keep it

inside. One of those plugs is visible above. I slotted the bent

tube with the Atlas milling machine.

The

gear guard started out as a 16 inch long piece of 3/4 inch square

welded tubing, which I was able to bend cold with the aid of a cheater

bar and a piece of heavy steel tubing that was just the right diameter

around which to form the more-than-180 degree curve of the guard.

A bar clamp allowed me to complete the bending task, as it let me bend

the tubing with my own hands without great effort. Of course, I

filled the tube with fine sand and hammered in oak plugs to keep it

inside. One of those plugs is visible above. I slotted the bent

tube with the Atlas milling machine.

|

The slotting went uneventfully, as the tube's sides did not try to

clamp the sides of the 3/8 inch wide milling cutter. To center

the slot, I milled all the way around the guard and then reversed the

guard in the vise.

The slotting went uneventfully, as the tube's sides did not try to

clamp the sides of the 3/8 inch wide milling cutter. To center

the slot, I milled all the way around the guard and then reversed the

guard in the vise.

After that, it was just a matter of judiciously sawing

tabs into the ends of the guard to fit the shape of the housing of the

gear drive. Lots of filing and even some work with a jewelers saw to

avoid struggles with clamping the guard in the bench vise.

Lastly, I drilled the four attachment holes in the guard,

clamped the guard onto the housing, and prick punched the sites to

drill and tap the housing for No.10-32 tpi cap screws. I opened

up

the clearance holes to 17/64 and did have to file one attachment hole

oval to clear its screw. It's very rigid and guards the delicate

worm gear nicely.

|

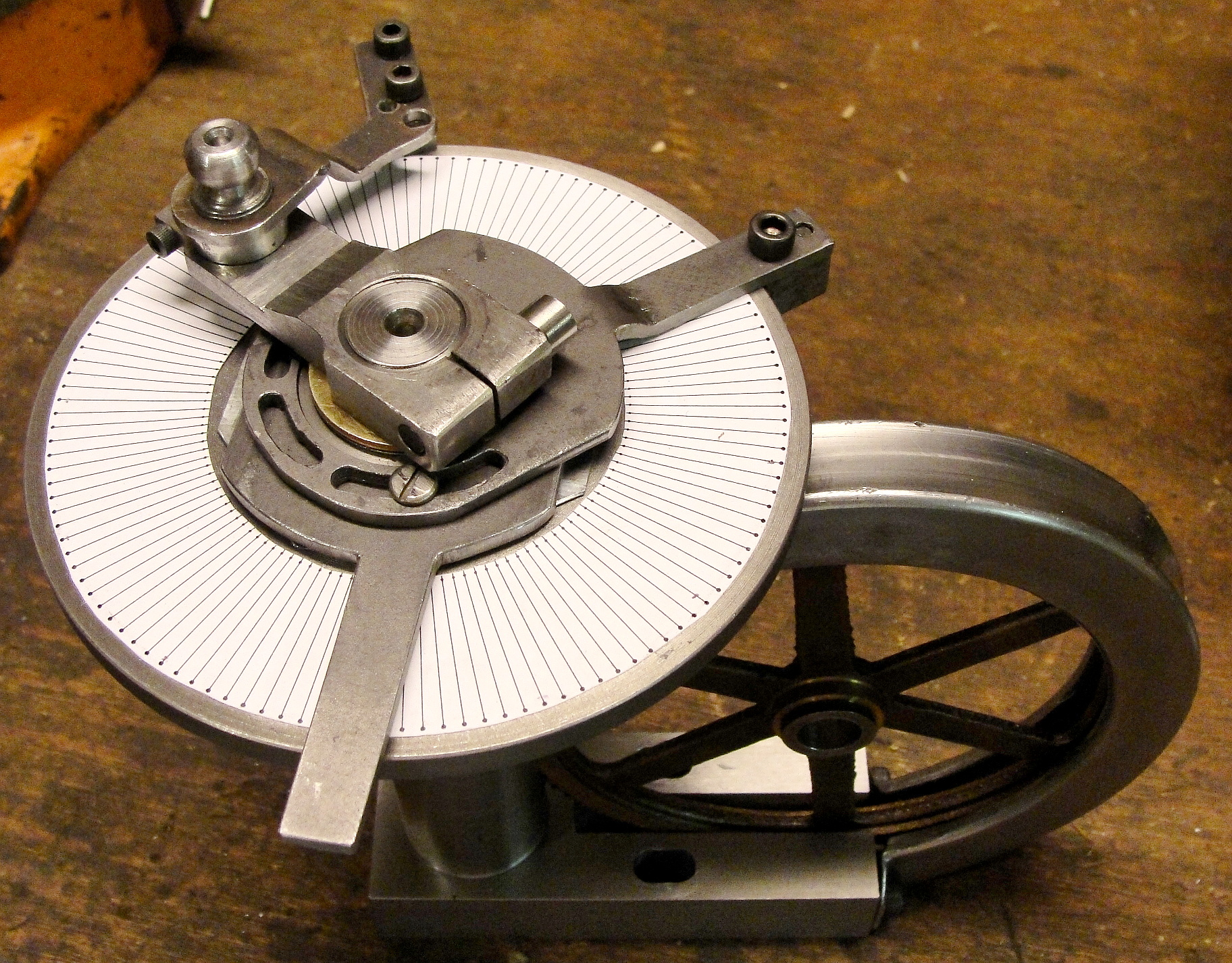

The little cross pin that I used to lift the index plunger is

too small in diameter for my fingers, so I made a tubular lifter and

cut tabs from the tube as shown at left. Now it's easy to lift

and twist the plunger in order to latch it into place while cranking

the worm gear to the next index position with no risk of catching the

sector and moving it.

I also added a clamp to one of the sector arms as seen at the rear of

the right- hand arm in the image at left.

|

The indexer is

adjusted for zero backlash when the housing

of the worm gear is clamped to the table of the milling machine. Then

the end play is taken out of the worm gear by loosening the crank's

clamp screw and screwing the crank down onto the upper thrust

bearing. Tightening the clamp screw of the crank takes up a

little more end play, so this is a trial-and-error process to eliminate

all the backlash in the indexing mechanism. The indexer is

adjusted for zero backlash when the housing

of the worm gear is clamped to the table of the milling machine. Then

the end play is taken out of the worm gear by loosening the crank's

clamp screw and screwing the crank down onto the upper thrust

bearing. Tightening the clamp screw of the crank takes up a

little more end play, so this is a trial-and-error process to eliminate

all the backlash in the indexing mechanism.

The gear guard not only protects the worm gear from

inadvertent impacts, it also shields the gear from chips, as they

cannot

land in the teeth of the worm gear. I do not have to remove the

guard while mounting/demounting the accessory.

|

Part IV - Making indexing plates

In order to drill the properly spaced holes in any new

index plates that I might make, I needed an adapter to present the disk

at right angles to the Atlas MM's spindle. I found a two inch

wide piece of half inch thick CRS which I draw filed flat to within

0.001 inch.

Then I drilled and countersunk two holes for 3/6-16 tpi

cap screws to clamp this plate to the table, installed two 5/16-18 tpi

studs and cut keyways in the plate for the indexing center's two 3/8

inch wide keys, and then fitted the worm gear accessory described above.

|

The Craftsman four inch chuck, while nicely made and fairly rigid,

doesn't hold the disk securely for drilling, so I made a dedicated

adapter threaded 1-10 tpi to fit the spindle nose of the indexing

centers by chasing the threads in my South Bend lathe and then

finishing the face and shoulder while the adapter was screwed onto

another 1-1/2-8 tpi to 1-10 tpi adapter that I made years ago.

|

The worm-gear accessory is just one

way of indexing the holes in the planned disks. I can just use

another gear with a 3/4 inch bore right on the back end of the indexing

center's spindle, or a different size bore (such as the South Bend

lathe's 9/16 inch bore change gears) mounted on a suitable adapter made

for the 80-tooth worm gear accessory. In the image immediately

above right I have mounted the angle-iron adapter made for that latter

purpose onto the half-inch-by-two-inch CRS plate. For example, I

can use the 127-tooth, 48 DP gear for the Derbyshire instrument lathe

as the template for drilling the 127-hole circle in a blank indexing

plate. The holes in the 5.0 inch diameter indexing disk would

have to be smaller than 4.75Pi/127 = 0.115 inch in diameter in

order not to part the disk [simple solution added in November 2016: don't drill clear through

the disk !].

|

|

|

Here's my proposed solution:

Use a plotting program (here: PSI-Plot, running under Wine on a laptop

running linux) to lay out 127 dots in a circle slightly smaller than

the OD of the cast iron disk, with radial lines passing through each

dot. The template is attached to the disk with Scotch double-sided tape

and aligned within one-dot-width to the circumference of the disk; the

double-sided tape doesn't "grab" the paper, so it can be pushed around

with the dividers that I used to check the aligment and then pressed

into place, where the sector arms and their clamps don't interfere with

the paper.

|

Note: Right-click and select "view image" to see these pictures full size, whereupon the radial lines will look OK.

|

|

With the setup shown above, left,

the sighting tube that I had just attached to the crank arm was about

chin-high, so I had to use an angled dental mirror and (occasionally)

an LED flashlight to see the dots as shown approximately in the

photograph at right. This was easier than it looks, and I completed

drilling the 127 holes in about two hours.

|

|

|

|

In

the third image I have

re-plotted the 127 hole locations on a 4.64 inch circle, converted the white

background to transparency, and fitted the plotted circle's small white

dots to the image of the disk. I had to adjust the width and height

of the disk image to fit the calculated circle of holes because the Epson plotter may not

be as accurate as my PSI-Plot plotting program.

There are actually 127 holes in the disk !

|

My

next step will be to countersink these

1/16th inch holes to set the sector arms with my original indexing

setup, and then to drill another 127 holes in the second disk. Each

pair of the 127 holes lies on 0.115 inch centers. View the overlain

disk full size to view the hole alignments.

|

|

Just as I did for

my

Just as I did for

my  The

adapter

also

has a sleeve to match the bore of the gear being used

as a template to the diameter of the adapter plug.

The

adapter

also

has a sleeve to match the bore of the gear being used

as a template to the diameter of the adapter plug.

Another

necessary

part

of

the above adapter is an angle plate that

holds the indexing pawl, which simply clamps to the table of the Atlas

milling machine.

Another

necessary

part

of

the above adapter is an angle plate that

holds the indexing pawl, which simply clamps to the table of the Atlas

milling machine.

While rummaging through my parts drawers in

search of 32 DP gears, I came across this 80-tooth worm gear.

That's just twice the number of teeth in a standard universal index's

40-tooth worm gear, so I decided to put my found gear to use.

While rummaging through my parts drawers in

search of 32 DP gears, I came across this 80-tooth worm gear.

That's just twice the number of teeth in a standard universal index's

40-tooth worm gear, so I decided to put my found gear to use.

The indexing plates came from a CRAFTS of NJ tailgating session, I

think ... or from a Cabin Fever auction ... I made the crank from

scratch, using the experience I gained from making a banjo for my

The indexing plates came from a CRAFTS of NJ tailgating session, I

think ... or from a Cabin Fever auction ... I made the crank from

scratch, using the experience I gained from making a banjo for my

The

gear guard started out as a 16 inch long piece of 3/4 inch square

welded tubing, which I was able to bend cold with the aid of a cheater

bar and a piece of heavy steel tubing that was just the right diameter

around which to form the more-than-180 degree curve of the guard.

A bar clamp allowed me to complete the bending task, as it let me bend

the tubing with my own hands without great effort. Of course, I

filled the tube with fine sand and hammered in oak plugs to keep it

inside. One of those plugs is visible above. I slotted the bent

tube with the Atlas milling machine.

The

gear guard started out as a 16 inch long piece of 3/4 inch square

welded tubing, which I was able to bend cold with the aid of a cheater

bar and a piece of heavy steel tubing that was just the right diameter

around which to form the more-than-180 degree curve of the guard.

A bar clamp allowed me to complete the bending task, as it let me bend

the tubing with my own hands without great effort. Of course, I

filled the tube with fine sand and hammered in oak plugs to keep it

inside. One of those plugs is visible above. I slotted the bent

tube with the Atlas milling machine. The slotting went uneventfully, as the tube's sides did not try to

clamp the sides of the 3/8 inch wide milling cutter. To center

the slot, I milled all the way around the guard and then reversed the

guard in the vise.

The slotting went uneventfully, as the tube's sides did not try to

clamp the sides of the 3/8 inch wide milling cutter. To center

the slot, I milled all the way around the guard and then reversed the

guard in the vise.

The indexer is

adjusted for zero backlash when the housing

of the worm gear is clamped to the table of the milling machine. Then

the end play is taken out of the worm gear by loosening the crank's

clamp screw and screwing the crank down onto the upper thrust

bearing. Tightening the clamp screw of the crank takes up a

little more end play, so this is a trial-and-error process to eliminate

all the backlash in the indexing mechanism.

The indexer is

adjusted for zero backlash when the housing

of the worm gear is clamped to the table of the milling machine. Then

the end play is taken out of the worm gear by loosening the crank's

clamp screw and screwing the crank down onto the upper thrust

bearing. Tightening the clamp screw of the crank takes up a

little more end play, so this is a trial-and-error process to eliminate

all the backlash in the indexing mechanism.