How would you expect the longigudinal versus transverse properties of this specimen to compare ?

Imagine what the longitudinal section looks like in comparison with the wrought iron previously discussed and then look at the answer below.

|

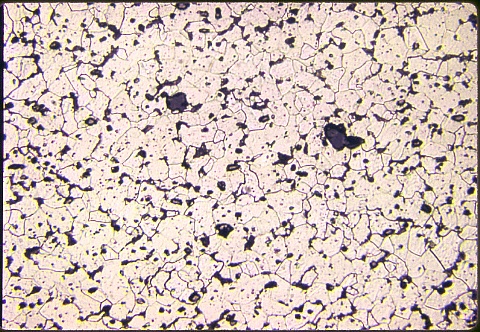

Here we have a free machining steel, shown as a transverse

section at 200X with a Nital etch. The material is AISI B1112

steel. The dark phase is manganese sulfide (MnS) which has the

FCC crystal structure of sodium chloride (NaCl) and which is quite

ductile at hot working temperatures, in contrast to ferrous sulfide

(FeS) which has a hexagonal crystal structure. How would you expect the longigudinal versus transverse properties of this specimen to compare ? Imagine what the longitudinal section looks like in comparison with the wrought iron previously discussed and then look at the answer below. |