Internalizing the risk of deep-ocean oil exploration.

Tell 'em you read it first here ... Copyright 2010 by George Langford, Sc.D.

| It

recently came to light that none of the companies drilling deep-ocean

oil wells have any viable plans to recover oil that escapes from a

failed well. This is my thought process for internalizing the cost and risk of drilling in the deep ocean. Internalization vs. externalization are terms that apply to the actions of folks that look on human life as a cooperative undertaking versus the actions of other folks that go about their lives like the players in a zero-sum game. Cigarette marketing externalized the health costs of smoking. Drug smuggling externalizes the social cost of addiction. Coal mining externalizes the societal costs of black lung disease, surface subsidence, acid mine drainage, montaintop removal, etc. Drunken drivers externalize the costs of their behavior and are sometimes required to make small restitution for the consequences of their actions, a form of internalization. Responsible automobile drivers purchase accident insurance and drive carefully in well maintained automobiles. Communities that take their drinking water from downstream of their sewage outfalls have to internalize the cost of all forms of treatment of their water. The following essay begins in the left-hand column and continues in the column at right. The left-hand column applies to the internalization of the risk of deep ocean drilling for oil. The right-hand column considers alternatives that might just yield greater and longer lasting returns on the investment of equivalent treasure and human lives, and which capture renawable resources instead of finite ones. |

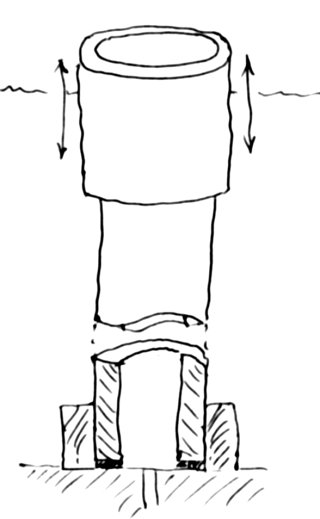

Prepare

to catch all the oil in a reservoir. This is what the

deep-drilling oil companies ought to have been required to do before

breaching that oil reservoir in the Gulf of Mexico.

|

Alternative use of all that concrete and steel:

Renewable-energy resources built on land or sea. Suggestions: 2. Wind farm on an artificial mountain or on top of an artifical ridge built of reinforced concrete to concentrate the air flow. The blades could be raised higher and be made larger this way than they can be made now, supported only on metal towers. 3. Vertical wind tunnel, using Bernoulli's theorem to create differential pressure by the flow of air across a tall open-ended cylinder made of reinforced concrete. Prairie dogs invented this technique for air-conditioning their burrows. 4. Vertical wind tunnel, using the lower density of moist air and extraction of the resulting rain to generate updraft, like a thunderstorm, but contained inside a cylindrical, reinforced concrete tower (not my idea ... GL, ed.) Because the air cools as it rises, extraction of the rain relieves the rising column of air of its burden of raindrops. These structures could also be a source of desalinated seawater. A large number of these could be co-located so as to form an artifical mountain that wouldn't present as much of a hazard as the same number dispersed over a large area. The array would help to cool the surrounding seawater and would generate an artificial pressure gradient, drawing air across warm seawater and enhancing the energy recovery from that moist air. 5. Concrete ships, anchored below the surface of the Gulf Stream, with water turbines suspended below to generate electrical power. These concrete submarines wouldn't get in the way of commercial shipping and would be less vulnerable to wave action during storms. 6. Desalination plants, each consisting of an evacuated concrete cylinder, with the upper end exposed to cool air at the upper end, where water evaporating from the sea surface would condense. Pipes in the walls of the cylinder would convey the salt-free water to holding tanks. The device would work like a heat pipe and would also cool the warm surface water. 7. Desalination plants, each consisting of an evacuated concrete cylinder, with the lower end exposed to cool water at the deep end, where water evaporating from the sea surface would condense. Pipes in the walls of the cylinder would convey the salt-free water to holding tanks. This device also would work like a heat pipe, cooling the warm surface water. What Congress should do: The deep-ocean drilling ventures should be required to include an economic plan to justify that the risk of failure is properly internalized and that a renewable energy-recovery plan with the same or greater expenditure could not produce the same present value as the recovery of the finite oil resource. If peer review reveals that the alternative, renewable-energy plan is actually less expensive than the deep-ocean drilling venture, then the proposed resources should instead be required to be applied to that renewable-energy venture. This discussion isn't much different from the one about storage of spent fuel rods from today's nuclear reactors. The cost of new nuclear plants should also be required to include internalized waste-handling plans and their costs should also be compared to renewable energy devices. |