Illustrated

catalog given to Lamar Lyndon ca.1890. The firm was located at

North Fifteenth Street & Pennsylvania Avenue, Philadelphia,

Pennsylvania.

Webpage copyright © George Langford 2010

|

Illustrated

catalog given to Lamar Lyndon ca.1890. The firm was located at

North Fifteenth Street & Pennsylvania Avenue, Philadelphia,

Pennsylvania.

Webpage copyright © George Langford 2010

|

|

|

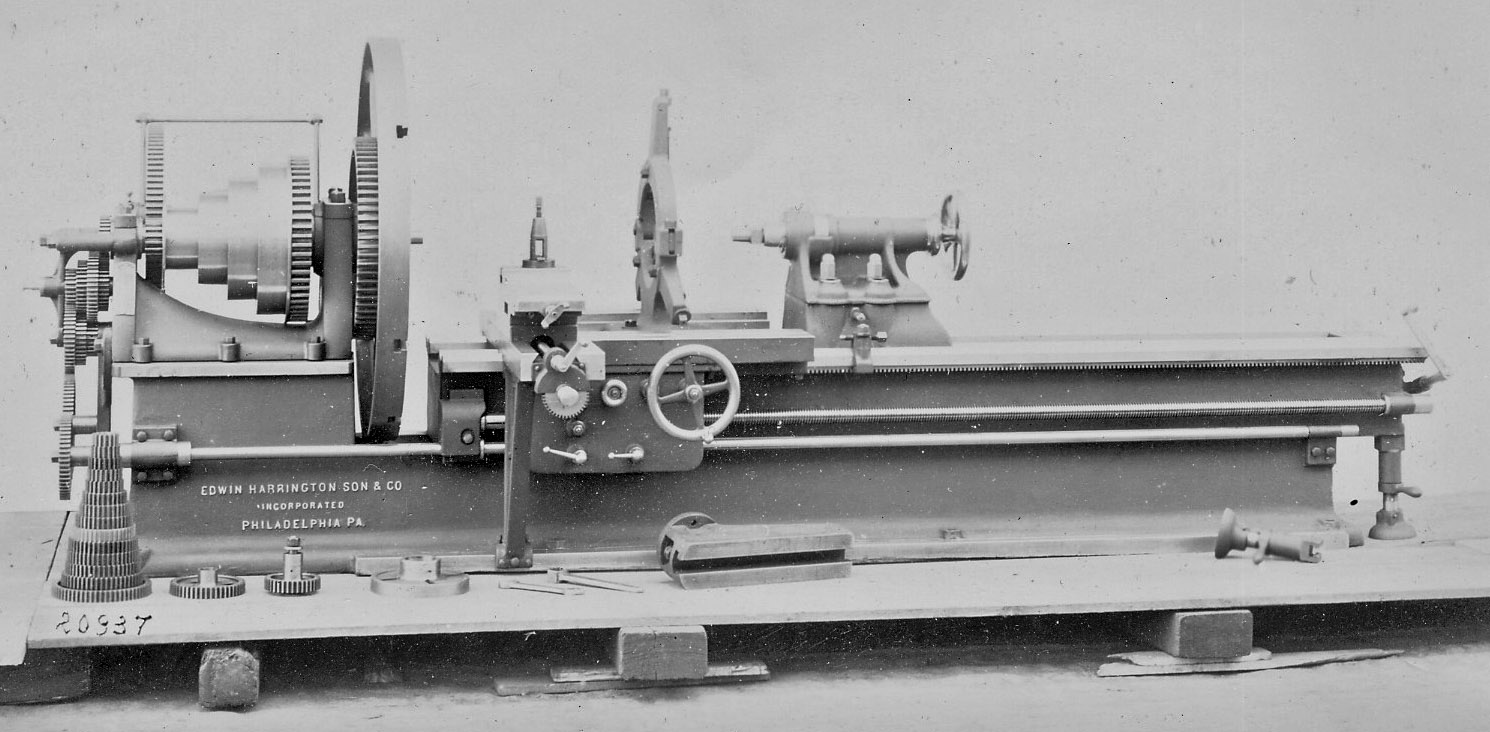

EXTENSION LATHE.

Designed especially for use in repair or jobbing shops; also

improvement on Gap Lathe page 39; the gap may be made wide or narrow to

suit width of work, while in Gap Lathe, the gap remains the same; this

also allows turning of a much longer shaft, as the distance between

centres may be doubled by extension of top portion of bed. 28 and 48 Inches Swing. Swings 28 inches over top shears; 21 inches over carriage: 48 inches over lower guides through gap; cone has 4 sections 3½ inch face; back geared, and geared face plate; extra tool block for turning pulleys 48 inches diameter; top slides are carefully fitted to lower guides, to be drawn back by means of hand wheel and screw at rear end; carriage will traverse full length of top  |

slides when drawn back;

overhang of carriage for turning swing of lathe is rigidly supported by an angle or bracket, having an adjustable shoe, on guide, on bottom of bed; this insures a firm support for the tool, so that a heavy cut may be taken when turning 48 inches diameter. Carriage has long bearings (giving greater bearing surfaces), which are self-oiling, decreasing the liability to wear the guides when used on short work; forged steel spindles; bronze metal boxes; Morse Standard Taper in lathe and drill press spindles; dead spindle clamped by adjustable conical binder; hand movement of carriage by means of hand wheel and pinion engaging in steel rack on bed. Steel rack put on in sections, enabling repair of broken cogs by supplying a new section. Independent geared friction feed, cross feed, and reverse feed motions in apron attached to carriage; turning and screw cutting feeds cannot become engaged at the same time. Lead screw on front of lathe is made of steel, and is clamped by open and shut nut; screw threads are only used when cutting screws. Countershaft; hangers; 3 pulleys, 22x8. to run 70 turns per minute. Screw gearing; steady and following rests; large and small face plates; steel wrenches; wrought-iron handles, and cross feed stop, are included. All gearing is cut. All smaller pinions are of steel. With 12½ feet bed; 8 feet centres, when closed; 16 feet when drawn back; cross feed and compound rest; shipping weight 8000 lbs, Price, $1200.00. Per extra foot of bed, $ Boxing for foreign shipment, $ |

|

EXTENSION LATHE.

Designed especially for use in repair or jobbing shops; also as

improvement on Gap Lathe- page 39; the gap may be made wide or narrow

to suit width of work, while in Gap Lathe, the gap remains the same,

this also allows turning of a much longer shaft, as the distance

between centres may be doubled by extension of top portion of bed.25 and 39 Inches Swing. Swings 25 inches over top slides; 19 inches over carriage; inches over lower guides through gap; cone has 4 sections 3½ inch face; back geared and geared face plate; extra tool block for turning pulleys 39 inches diameter; top slides are carefully fitted to lower guides to be drawn back by means of hand wheel and screw at rear end; carnage will traverse full length of top slide when drawn back; extended portion of carriage for turning full swing of lathe is rigidly supported by an angle or bracket, having an adjustable shoe, on guide on bottom of bed; this insures a firm support for the turning tool, so that a heavy cut may be taken when turning 39 inches diameter. Carriage has long bearings (giving greater bearing surfaces), which are self-oiling, decreasing the liability to wear the guides when used on short work; forged steel spindle, bronze metal boxes; dead spindle clamped by adjustable conical binder Morse Standard Taper in lathe and drill press spindles; hand movement of carriage by means of balance wheel and steel pinion engaging in rack on bed. Steel rack put on to sections, enabling repair of broken cogs by supplying n a new section. Independent geared friction feed, cross feed. and reverse feed motions in apron attached to carriage turning and screw cutting feeds cannot become engaged at the same time. Steel lead screw on front of lathe is clamped by open and shut nut; screw threads are used only when cutting screws, Countershaft; hangers: 3 pulleys, 7x16, to run 68 turns per minute, for regular work; 2 pulleys, 4½x20 inches, to run 68 turn, for turning full swing through gap. Screw gearing; steady and following rests; large and small face plates; steel wrenches; wrought iron handles and cross feed stops included. All gearing is cut. All smaller pinions are of steel. With 12 feet bed; 8 feet between centres, when closed, 16 feet when extended, with compound rest and cross feed; shipping weight. lbs. Price, $ Per extra foot of bed, $ Boxing for foreign shipment, $ |

EXTENSION LATHE.

Designed especially for use in repair or job shops: also as improvement

on Gap Lathe, page 39. The gap may be made wide or narrow to suit width

of work, while in gap lathe the gap remains the same. This also allows

turning of a much longer shaft, as the distance between centres may be

doubled by extension of top portion of bed.30 and 60 Inches Swing. Swings 36 inches over top shears; 25½ inches over carriage; 60 inches over lower guides through gap back geared and geared face plate, 48 inches diameter, keyed to spindle, unless otherwise ordered; top slides are carefully fitted to bottom guides, to be drawn back by means of a hand wheel and screw at rear end; carriage will traverse full length of top slide when drawn back. Overhang of carriage for turning full swing of lathe, rigidly supported by an angle or bracket, having an adjustable shoe on guide on bottom of bed. This insures a firm support for the turning tool, so that a heavy cut may be taken when turning 60 inches diameter. Carriage has long bearings, giving greater bearing surfaces, which are self-oiling, decreasing the liability to cut the guides when used on short work; forged steel spindles; bronze metal boxes; dead spindle clamped by adjustable conical binder, hand movement of carriage by means of balance wheel and steel pinion engaging in rack on bed. Steel rack put on in sections. enabling the repair of broken cogs by supplying a new section. Independent geared friction feed, cross feed and reverse feed motions in apron attached to carriage. Lead screw on front of lathe is made of steel, and is clamped by open and shut nut. Screw threads are only used when cutting threads. Countershaft; hangers; 3 pulleys. 8x24, to run 65 turns per minute; screw gearing; steady rest; steel wrenches, wrought-iron handles and cross feed stop are included. With 14-feet bed : 8-feet centres when closed ; 16-feet when opened or drawn back; compound rest; cross feed; shipping weight. lbs. Price, $ Per extra foot of bed, $ Boxing for foreign shipment. $ |

EXTENSION LATHE.

Designed especially for use in repair or jobbing shops; also as

improvement on Gap Lathe, page 39. The gap may be made wide or narrow

to suit width of work, while in Gap Lathe the gap remains the same;

this allows turning of a much longer shaft, as the distance between

centres may be doubled by extension of top portion of bed.48 and 72 Inches Swing. Swings 48 inches over top shears; 72 inches over lower guides through gap; 29 inches over carriage, cone has 5 sections, 4 inch face; back geared and geared face plate 60 inches diameter, keyed to spindle, unless otherwise ordered top slide, are carefully fitted on bottom guides. to be drawn back by means of screw at rear end; carriage will traverse full length of top slide when drawn back; overhang of carriage, for turning full swing of is lathe, is rigidly supported by an angle or bracket having an adjustable shoe on guide on bottom of bed, This insures a firm support for the turning tool, so that a heavy cut may be taken when turning 72 inches diameter. Carriage has long bearings (giving greater bearing surfaces), which are self-oiling, decreasing the liability to cut the guides when used on short work; forged steel spindles; bronze metal boxes; dead spindle clamped by adjustable conical binder; hand movement of carriage by means of hand wheel and steel pinion engaging in rack on bed. Steel rack put on in sections, enabling the repair of broken cogs by supplying a new section. Independent geared friction feed, cross feed and reverse feed motions in apron attached to carriage. Lead screw on front of lathe is made of steel, and is clamped by open and shut nut. Screw threads are only used when cutting threads. Countershaft; hangers; 3 pulleys, 24x8, to run 53 turns per minute; screw gearing; steady rest; steel wrenches; wrought-iron handles and cross food stop are included. With 15 feet bed ; 8 feet between centres when closed; 16 feet when drawn back; cross feed; shipping weight, lb, Price. $ Per extra foot of bed. $ Boxing for foreign shipment, $ |